Diesel Generator Monitoring System

Generator remote monitoring checks, from a remote location, all parameters that may affect the service of the emergency power system. Bernini Design offers reliable solutions to upgrade your system. A typical application is a standby generator for critical applications like hospitals or shelters.

How Does Generator Monitoring Work?

It works by establishing a remote connection with your diesel generator through these ways:

Remote monitoring via GSM, TCP/IP and Modbus are the recommended ways to access a power generator from remote locations. The basic concept is to virtually transfer the control panel remotely. In other words, you have a generator placed in Argentina, but from your office in Australia, you will act as being in front of the generator. Bernini Design provides a generator remote monitoring equipment, hardware, and software, to manage a Diesel Generator placed in a Base Transceiver Base (BTS).

It is about a shelter or a building that includes fundamental equipment that allows wireless communication between the user equipment and a network. The user equipment may include mobile phones, tablets, radio equipment, and computers. This includes wireless Internet connectivity. The purpose of a diesel generator monitoring system is to reduce the operating costs for maintenance. When an outage does occur, service personnel can be dispatched with valuable information regarding what problems they may encounter on-site. A diesel generator monitoring system plays an important role in preventing and reducing network outages caused by generator troubles. You can set pre-alarms and you can modify the settings of the engine or generator. This will avoid severe damage to the system. The DIESEL GENERATOR MONITORING SYSTEM can monitor the parameters of the utility power to the site, rectifiers & batteries, air conditioner, and other hybrid power types of energy sources.

TCP/IP GENERATOR REMOTE MONITORING

Bernini Design provides TCP-IP-based diesel generator remote monitoring systems. The diesel generator plays an important role in case of a prolonged power outage. Generator remote monitoring allows an accurate analysis of the diesel generator to prevent issues that might affect the service of the emergency power system. The Bernini Design's Generator remote monitoring systems drastically reduce operating costs and maintenance. When an outage does occur, service personnel can be dispatched to the power generator site with important information regarding what problems they may encounter. By using our TCP-IP server you built a state-of-art real-time internet-based monitoring system. Our TCP-SERVER features all hardware security components to prevent

TCP-IP SERVER

299€

FREE SHIPPING

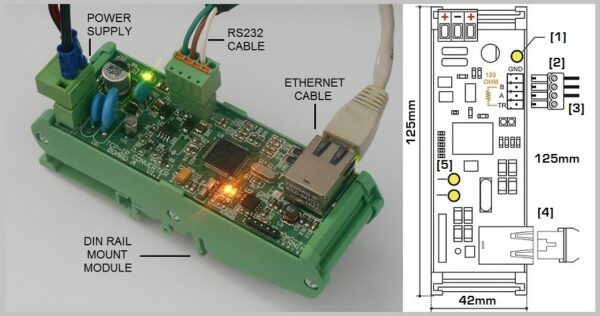

You are required to connect the TCP-IP SERVER to the ROUTER by using an ETHERNET cable. You have to use the RS485 cable to connect the TCP-IP SERVER to a Bernini Design generator controller. The RS485 connection allows up to 1000m distance between the generator controller and TCP-IP SERVER. Both types of equipment can be connected to the engine battery. The power consumption of the TCP-IP SERVER is only 100mA when operating at full speed. The module can operate in a wide temperature range of -25 up to 70 degrees Celsius. Follow the steps in the user manual to configure the TCP-IP SERVER.

INDUSTRIAL GENERATORS GSM MONITORING

The top results of a good GSM monitoring system are obtained when there are no compromises on the quality and performance of the generator controller. The Be124 GSM system is the best example.

The diesel generator remote monitoring via SMS is the most simple, user-friendly monitoring solution. Firstly it is particularly used when Fuel Level monitoring is an important issue. This is the case for mobile operators in areas subjected to prolonged power outages. The generators are always located in remote places. Secondly, fast-responding remote equipment together with good diesel fuel sensing devices can prevent theft and will allow you a better scheduler of refuel visits. This will prevent the shutdown of a remote site due to running out of fuel. The Bernini Design generator controllers feature a programmable automatic 'FUEL CHANGE' notification.

BE16-124 SMS MONITORING USER MANUAL

The kit consists of the following parts:

1) The F1403 industrial modem

2) GSM antenna

3) Be16-124 gateway module

4) Set of cables, accessories and user manual

AMF PANELS GSM MONITORING

When it is to Automatic Mains Failure panels we recommend the BeK3 GSM kit. After installing the system you can get full control of the AMF PANEL using SMS commands.

In the above example, the GSM kit is embedded in the panel. The antenna is placed on the top of the panel. By sing the Be16-K3 gateway you are able to fully control the panel functionality. You can start the generator via a SMS command. In the same way you can transfer the LOAD form MAINS and GENERATOR. Not mentioning that you will receive a detailed notifications about all events.

BE16-K3 GSM GATEWAY INSTRUCTION MANUAL

PURCHASE THE GSM KIT FOR YOUR APPLICATION

When you make an order specify the kind of the controller you want to connect: Be124, BeK3 or Be142. Each controller features a different set of MODBUS register.

BE16 GSM GATEWAY

249€

FREE-SHIPPING WORLD-WIDE

You can pay online or ask for a Proforma Invoice and pay via bank transfer

SUPPORT

+39 335 70 77 148

bernini@bernini-design.com

MODBUS MONITORING

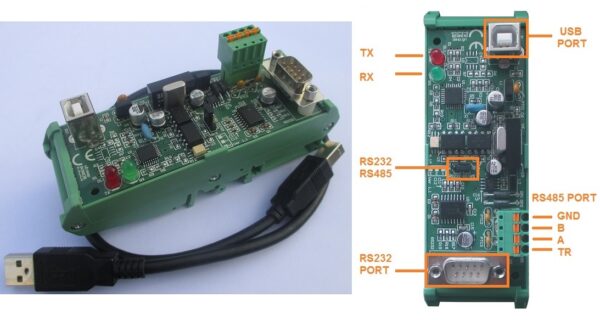

Direct MODBUS communication is the easiest way to control and monitor a diesel generator. Connect the MOD-BUS to the USB converter to a Bernini Design generator controller. Use a twisted pair cable. The <be124 generator controller, for example, can drive a cable as long as 1000 meters. Connect a computer with a USB interface. Run the Bernini Design application software to connect the computer to the generator.

RS485-USB

149€

FREE SHIPPING

Zona Industriale

46035 Ostiglia Italy

bernini@bernini-design.com

+39 335 70 77148