Generator Controllers Manufacturer

Bernini Design manufactured generator controllers since 1984. It is one of the oldest and most experienced companies with a wide range of experience worldwide,

First, choose on this page the generator controllers suitable for your application. Second, check our offer. Our range of generator controllers will satisfy your industrial, commercial and telecom standby system requirements.

GENERATOR CONTROLLERS OR GENERATOR CONTROL PANELS?

Choose your language, or stay tuned on this page in English language.

PRODUZIONE CENTRALINE ELETTRONICHE E QUADRI AUTOMATICIPER GRUPPI ELETTROGENI

Ofrecemos una amplia gama de controladores para grupos electrógenos y para cuadristas

Qu'est-ce qu'un contrôleur de groupe électrogène?

Steuerungen für Stromaggregate

Kiedy generator diesla pracuje w ekstremalnych warunkach klimatycznych, konieczne jest zainstalowanie niezawodnego sterownika agregatu prądotwórczego.

Producem şi dezvoltăm controlere şi sisteme electronice pentru automatizare generator

Generator Styrenhet Automatisk Start Kontrollpanel

Generator controllers price

We can sell samples, in small quantities and large quantities. With VOLUME PRICING we motivate our customers to purchase in larger quantities by offering a lower per-unit price once they reach a certain volume. The generator controller price for samples or small quantities includes the freight. In the case of large quantities, a deep analysis of many factors must be carried out.

INTEGRATED AMF ATS GENERATOR CONTROLLER SUITABLE FOR AMF PANELS

This is the best option when you manufacture AMF and ATS panels. This is a cost-effective product compact, and reliable.

VOLUME-BASED PRICING AVAILABLE AT $89

AMF CONTROL PANEL TUTORIAL AND ONLINE PURCHASE PAGE

GENERATOR CONTROLLERS RATED -30°C-+85°C SUITABLE FOR TELECOM APPLICATIONS

The combined AMF and GENERATOR controllers feature the RS485 serial interface. This is the best way to carry the MODBUS protocol. We design our accessories so that you can connect to more GSM and TCP/IP capable systems.

The generator controllers BE2K-PLUS are based on multiprocessor architecture consequently, the best solution for TELECOM BTS where an operating temperature range from -30°C to 85°C is mandatory.

SOLID ROCK, NO INTERFERENCES, ENCLOSURE MADE OF STEEL

READ MORE ABOUT BE2K-PLUS GENERATOR CONTROLLERS

Generator Controllers Leadership

There are leaders, and then there's everyone else. At Bernini Design when it is about generator controllers, we take immense pride in driving the generator controllers' standard forward. We focus from 1984, on efficiency, quality, and safety.

No one ever complained about our generator controllers

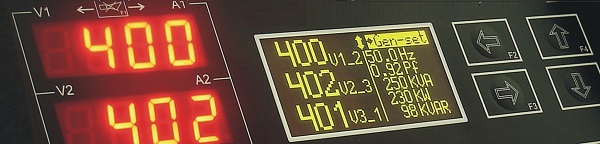

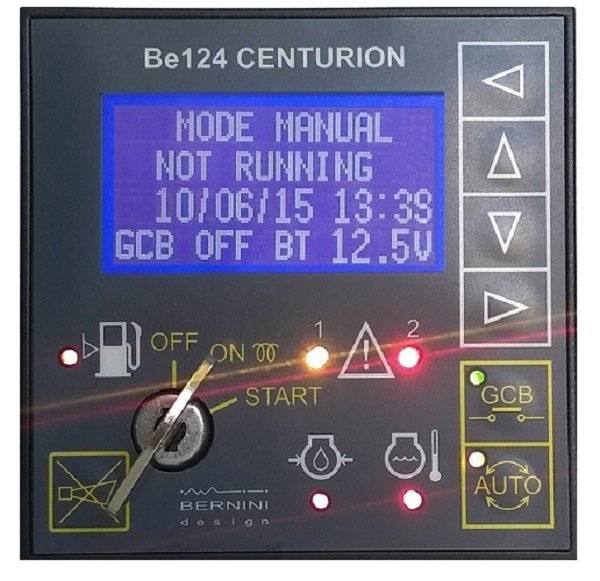

400Hz GENERATOR CONTROLLERS

This is our best offer for a generator controller for aircraft ground support machinery. The engine and generator control is the main focus of the Be124 design. The Be124 interfaces with J1939-compatible engines.

READ MORE ABOUT BE124 GENERATOR CONTROLLER

It works at 400Hz, consequently, you can use these controllers for generators' ground support units. These generator controllers feature extraordinarily advanced functions like oscilloscope and data logger,

THE BEK3

MULTIFUNCTION AMF/ATS

+ GENERATOR CONTROLLER

+ CANBUS

+MODBUS

The BeK3 generator controllers are designed for generator control panel manufacturers.

First, thanks to CANbus, and MODbus you can use these generator controllers when you require remote control and monitoring.

THE BEK3 AMF CONTROLLER PRESENTATION

Second, the embedded mains monitoring will allow you to manufacture AMF and ATS panels. Lastly, the metal cover offers extraordinary protection from overvoltages.

AMF PANELS VIDEO TUTORIAL

HEAVY DUTY KEY-START AUTO-START MODULE

Invest in our generator controllers. In many cases with less than $200, you can purchase a generator controller that, at the end, will double the value of your old generator. You can transform it into a good standby system.

You may need to add only 2 automotive relays. The Be24 generator controller is designed to interface with a generator as old as 40 years. Watch our online tutorial.

READ MORE OR PURCHASE THE BE24 GENERATOR CONTROLLER

Among the generator controllers for general purposes, the Be24 is the best choice. First, it withstands harsh conditions. Consequently is the best solution when it comes to industrial-grade generators.

VOLUME-BASED PRICING AVAILABLE AT $69

Add two relays to transform a second-hand generator into an automatic generating set.

Heavy duty auto-start module with remote control monitoring

volume-based pricing available at $59

The Be1 is a cost-effective generator control and monitoring module. You can remotely start and stop the generator via hardware contact or GSM.

The Be1 is a cost-effective generator control and monitoring module. You can remotely start and stop the generator via hardware contact or GSM.

PURCHASE THE BE1 GENERATOR AUTO START CONTROLLER

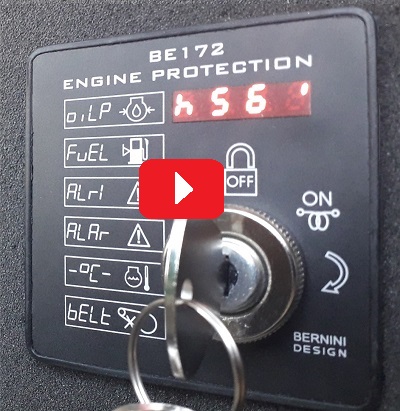

KEY START ENGINE -GENERATOR CONTROLLER

The Be172 is the smallest engine protection module with a powerful 30-amp key switch start.

READ MORE OR PURCHASE THE BE172 KEY START MODULE

Install it in a small generator, compressor, or agricultural machinery.

VOLUME-BASED PRICING AVAILABLE AT $49

It provides an automatic stop to prevent major damage to your engine.

The Be72 is a cost-effective, user-friendly engine protection module with a powerful 30-amp key switch start.

VOLUME-BASED PRICING AVAILABLE AT $39

READ MORE OR PURCHASE BE72 KEY START MODULE

Install it in a small generator, compressor, or agricultural machinery

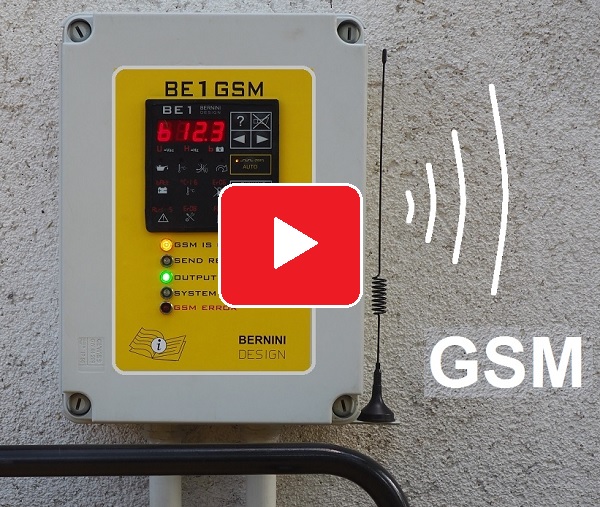

GENERATOR REMOTE MONITORING SOLUTIONS

The Bernini Design generator controllers feature the RS485 interface. Furthermore, by supporting the MODBUS-RTU, you benefit from extraordinary possibilities in remote control monitoring. We further support you with free-of-charge software tools. For example, you can make an AMF panel using the BeK£ controller.

BERNINI DESIGN GENERATOR CONTROLLERS FEATURE REMOTE MONITORING

Next, by adding the GSM gateway, you will have full control via SMS. Even more, by adding the TCP-IP server, you can get a connection to the internet.

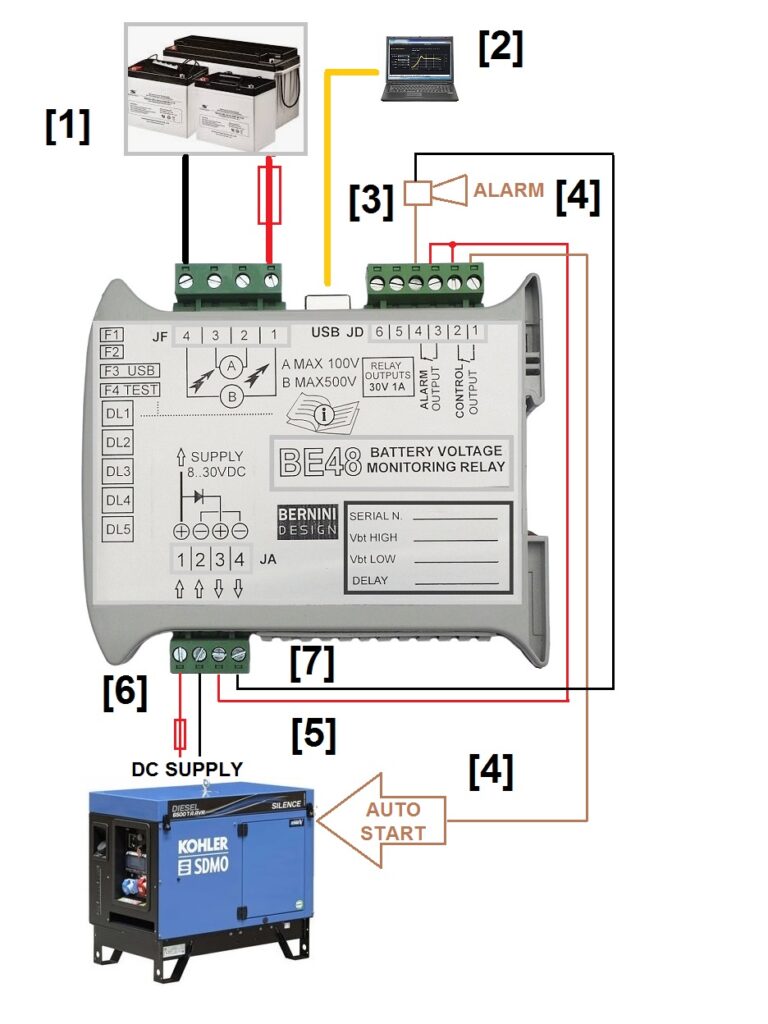

BATTERY MONITORING SOLUTIONS

Some of our generator controllers are specifically designed for battery monitoring. This is extremely important when generators are placed in remote locations. You can set up an automatic start based on the status of the battery. The battery will be ready all the time.

EXAMPLE OF REMOTE BATTERY MONITORING PANEL

The Be48 is the right product if your business is related to solar systems. The Be48 is a fully USB programmable monitoring relay. It will automatically start the engine when the battery is low.

It will automatically stop the engine when some adjustable conditions are met.

GSM START-STOP MODULE

The B148 relay is designed to start and stop an engine using SMS remotely.

GSM-BASED GENERATOR MONITORING SYSTEM

You will get the best from it when you wire its output to one of our auto-start modules like Be1, Be24, Be124 and all AMF and ATS controllers.

THE COST-EFFECTIVE ATS CONTROLLER

Use the Be242 when you make automatic transfer switch panels. You only need to make a single round hole. Consequently, you will save meters of cable. As a result, you will save money and time.

VOLUME-BASED PRICING AVAILABLE AT $129

The Be242 features an interface board that connects diesel, gasoline or gas engines.

The Be242 features an interface board that connects diesel, gasoline or gas engines.

READ MORE OR PURCHASE THE BE242 ATS CONTROLLER

BERNINI DESIGN MANUFACTURER OF TOP-QUALITY PRODUCTS

Our standards are high. We're so high we're in a league of our own, moving our entire industry forward. The manufacturers of Bernini Design Italy and Bernini Design Romania generator controllers have become synonymous with the highest quality.

No one ever complained about having their work executed perfectly.

Take advantage of our long-term experience. We provide you with the best tutorial that can help your business

The meaning of the generator control panel is unclear. This is mainly due to mixed information on the internet. Bernini Design has been a manufacturer of generator controllers since 1984

WHAT IS A GENERATOR CONTROL PANEL?

The definition of a generator control panel is crystal clear to us.

This is one of the most common questions made on search engines. There are miscellaneous answers. The result is only a big confusion.

Let Bernini Design clarify all your doubts once in a while

WHAT ARE THE DIFFERENCES BETWEEN AMF AND ATS?

The "Mains" is a British term indicating the public utility power. In other words, the "Mains" is the power national grid. In between the Mains and your load, there is the energy counter. In America, the"Mains" is meant to be the Utility Power grid.

An electronic or electric system that detects a deviation of the electrical parameters is considered to be a MAINS FAILURE DEVICE

The definition of a generator controller is rather vague. The continuous integration of the electronic components and processors expands the functionality of a generator controller

This is our definition of generator controller

WHAT IS A GENERATOR CONTROLLER?

WHAT IS A GENERATOR AUTO-START MODULE?

WHAT IS GENERATOR REMOTE MONITORING?

HOW TO HOOK A GENERATOR TO YOUR HOUSE?

IS INSTALLING AMF PANELS YOUR CORE BUSINESS?

BROWSE OUR AUTOMATIC MAINS FAILURE PANELS

LOOKING FOR COST-EFFECTIVE PANELS?

Our factory, located in Romania can manufacture at competitive price generator control panels suitable for your application.

BROWSE OUR OFFER OF 15-160KVA ATS PANELS

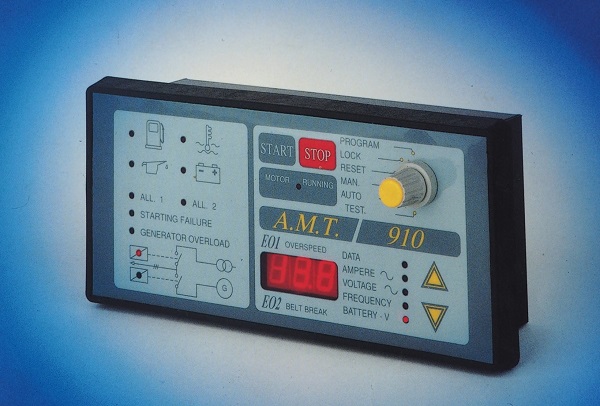

1980-2010 GENERATOR CONTROLLERS

We started our business in 1984. Since then over 400.000 generator controllers have been running worldwide. The following generator controllers are available for you on request.

AMT910 AMT920 BE11 AMF CONTROLLER

The AMTXX controllers areno longer available. But you can replace this unit with Be21. It is fully compatible.

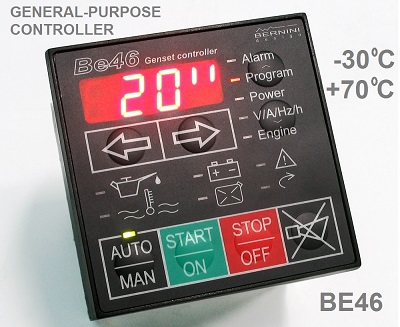

Be23 Be46 GENERATOR CONTROLLER

MADE ON REQUEST ONLY 299€

The Be46 is the recommended replacement for BE23

SEND US THE BE23 CONTROLLER FOR SERVICE

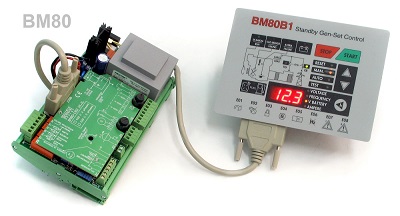

THE BM80 GENERATOR CONTROLLER

It is about a general-purpose 3-phase automatic mains failure which monitors two wires from the alternator up to 500V. It features a battery charger.

MADE ON REQUEST ONLY 399€

READ MORE OR PURCHASE THE BM80 CONTROLLER

BE21 GENERATOR CONTROLLER

It is about a general-purpose single-phase automatic mains failure first designed in 1990 with the name AMT910, then Be11 in 1998, then Be21 in 2002. There are over 100.000 Be21 working worldwide.

MADE ON REQUEST ONLY 299€

READ MORE OR PURCHASE THE Be21 CONTROLLER

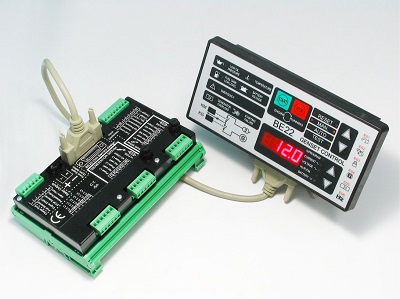

THE BE22 GENERATOR CONTROLLER

This is the big brother of Be21. The Be22 is fully 3-phase first designed in 2003. There are over 50.000 Be22 working worldwide. The Be242 is recommended for Be22 replacement.

MADE ON REQUEST ONLY 499€

READ MORE OR PURCHASE THE Be22 CONTROLLER

BE42 GENERATOR CONTROLLER

This is the big brother of Be21. The Be42 is fully 3-phase first designed in 2006. There are over 150.000 Be42 working worldwide. For new applications, we recommend that you install the Be242 which is fully compatible with the user interface point of view

MADE ON REQUEST ONLY 329€

READ MORE OR PURCHASE THE Be42 CONTROLLER

BERNINI DESIGN SRL

Industrial Park

46035 OSTIGLIA

ITALY

SUPPORT

+39 335 70 77 148