What is a generator auto start kit?

It is an electronic controller capable to automatically start and stop a generator. Additionally, it offers several ways to activate to initiate the automatic start; from a digital input, from a software request or in case of low battery.

The generator auto-start modules Be1, Be24, Be124 or ATS CONECT can make this happen. You can refurbish your second-hand generator: it will start according to your settings. Follow our tutorial, and give a new life to your old generator by adding GSM remote control and monitoring.

The Be1 multifunction auto-start module

The Be1 is a multifunction generator controller. It features an RS485 serial port that fully supports the MODBUS-RTU protocol. You can optionally connect a GSM MODEM or a TCP_IP server.

PURCHASE THE BE1 GENERATOR AUTO-START CONTROLLER

You can set up five programmable inputs and four programmable outputs. It is the ideal choice for small single-phase generators.

Last but not least you can set up parameters for low-battery start.

5 CONFIGURABLE DIGITAL/ANALOG INPUTS

4 CONFIGURABLE DIGITAL OUTPUTS

SINGLE PHASE GENERATOR MONITORING 600V

9 PUSHBUTTONS 4DIGIT DISPLAY

MODBUS RTU

PICKUP MONITORING

CHARGER ALTERNATOR MONITORING

OVER 100 ADJUSTABLE SETTINGS

DIN96 CUT-OUT SIZE

A combined key-start and generator auto-start module

By installing the Be24 you can make a generator start automatically by programming a scheduler. In this way, your generator will regularly automatically start to keep the mechanical parts, lubricating, system and battery always active.

PURCHASE THE BE24 GENERATOR AUTO START CONTROLLER

Connect an external remote control module or an ATS panel to the REMOTE INPUT. You can easily get a 2 wire auto-start kit.

2 CONFIGURABLE DIGITAL INPUTS

4 DIGITAL INPUTS

5 DIGITAL OUTPUTS

SINGLE PHASE GENERATOR MONITORING 600V

SINGLE PHASE CURRENT MONITORING 500A

6 PUSHBUTTONS 4DIGIT DISPLAY

30AMP KEY SWITCH

PICKUP MONITORING

CHARGER ALTERNATOR MONITORING

32 ADJUSTABLE SETTINGS

DIN96 CUT-OUT SIZE

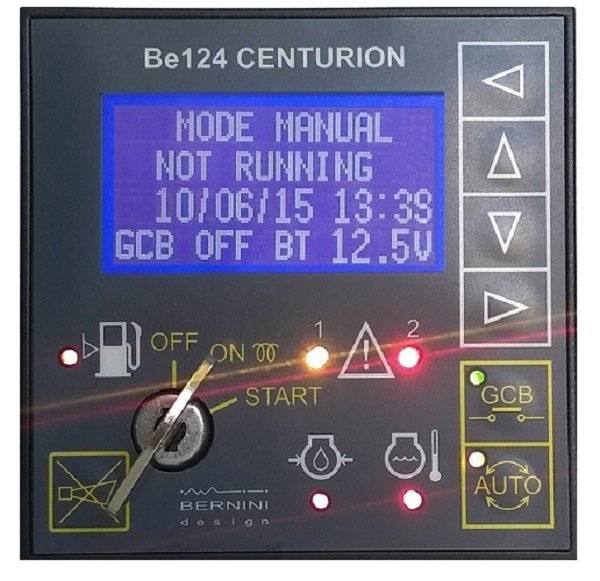

The Be124 multifunctional key-start and auto-start module

The advanced Be124 generator controller includes a DATA logger, a real-time oscilloscope, a real-time clock, CANbus, and a Modbus interface.

PURCHASE THE BE124 GENERATOR AUTO START CONTROLLER

With over 150 adjustable settings and offering GSM connectivity, the Be124 is the most advanced and compact generator auto start module.

MODBUS-RTU CANBUS J1939

3 CONFIGURABLE ANALOG INPUTS

3 CONFIGURABLE DIGITAL INPUTS

4 DIGITAL OUTPUTS

2 CONFIGURABLE DIGITAL OUTPUTS

3-PHASE GENERATOR MONITORING 600V

3-PHASE CURRENT MONITORING 1000A

EARTH-FAULT MONITORING 100A

7 PUSHBUTTONS 128X64 LCD DISPLAY

7 LED INDICATORS

30AMP KEY SWITCH

PICKUP MONITORING

CHARGER ALTERNATOR MONITORING

120 ADJUSTABLE SETTINGS

DIN96 CUT-OUT SIZE

DATA LOGGER

DIGITAL OSCILLOSCOPE

Which generator auto start is recommended for my application?

It depends on many factors. The following table may help you choose the right product for your application.

| Product

Function |

Be124 | Be1 | Be24 | Be46 |

| Single-Phase | Yes | Yes | Yes | Yes |

| 3-Phase | Yes | No | No | No |

| Current Single Ph. | Yes | No | Yes | Yes |

| Current 3-Phase | Yes | No | No | No |

| kW kVAr kVA Energy Counter | Yes | No | No | Yes |

| Graphic Display | Yes | No | No | No |

| Led Display (digits) | No | 4 | 4 | 4 |

| Leds count (Nos) | 7 | 6 | 2 | 12 |

| Push button count | 7 | 9 | 6 | 8 |

| Key Switch | Yes | No | Yes | No |

| Static Outputs | 6 | 4 | 5 | 8 |

| Digital Input | 3 | 3 | 5 | 5 |

| Sensor Inputs | 3 | 3 | No | 3 |

| Pick-up input | Yes | Yes | Yes | Yes |

| RS485 | Yes | Yes | No | No |

| CAN-BUS | Yes | No | No | No |

| MODBUS | Yes | Yes | No | No |

| Box Materials | Plastic | Steel | Plastic | Plastic |

Will an automatic generator start when the power goes out?

Yes, if it is supported by an Automatic Mains Failure Panel that features all input-output circuits capable of engine starting

How does a self-start generator work?

READ MORE ABOUT HOW TO CONNECT A GENERATOR TO YOUR HOUSE

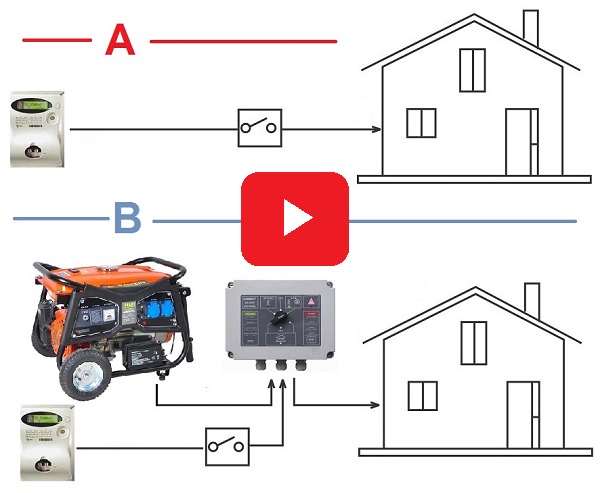

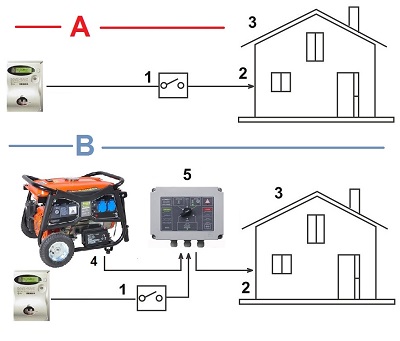

The controller on the generator continuously monitors the status of the utility power. This can be done directly (not recommended) or via a command from a VOLTAGE MONITORING RELAY. The controller will instruct the generator to start and stop following the status of the utility power.

Are you looking automatically to supply your house in case of power outages?

PURCHASE AN AUTOMATIC TRANSFER SWITCH FOR YOUR HOUSE

Yes, after setting up the auto stat module, the next easy step is to install a good ATS panel. There you are the tutorial.

HOW TO CONNECT A GENERATOR TO YOUR HOUSE?

In case of a power outage (1), the ATS panel (5) will instruct, via two wires, the generator to start. The Be24 will take care to monitor all parameters. After the automatic warm-up time, the ATS panel (5) will restore the electricity in your house. When the utility is stable, the ATS panel after switching the load, will instruct the Be24 to stop the engine.

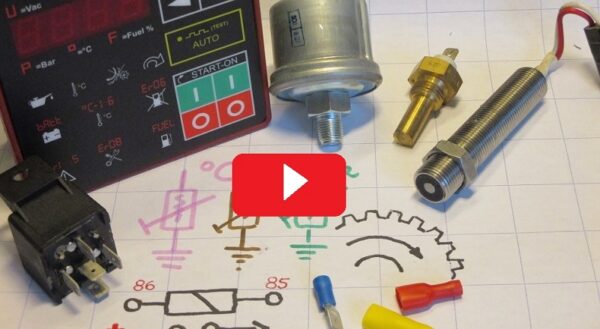

Generator automatic start module tutorial

The generator auto start module triggers the starting circuits when detecting a request from an Automatic Mains Failure relay, a general purpose normally open or closed contact, a software request via serial interface or when the battery is low. The starting circuits consist of pilot relays for fuel solenoid, pre-glow and electric start.

1) The generator is placed in a remote location. No utility power can recharge the battery. From time to time you need to start the engine. Your final goal is to recharge the battery.

2) Remotely start the generator to supply particular tools or machinery like an irrigation pump.

3) You need an automatic start in case of mains failure. In this case, we are talking about the Automatic Mains Failure controller. The most popular application is on a standby generator for your house.

HOW TO TRIGGER A GENERATOR AUTO-START MODULE?

There are several ways. The most common to trigger an auto-start controller is via a digital input. In other words, you connect a switch. It could be normally open or normally closed. The choice is based on your level of safety needs. Another common way is via analogue input. Based on adjustable settings, the generator will start and stop based on the level of a DC voltage. This is the case with low battery voltage monitoring. You set a start threshold and you set a stop voltage threshold. Advanced monitoring systems feature timers to control the start and stop delays.

The advanced ways to trigger the automatic start module are from the GSM or TCP_Ip request. In industrial applications, the simplest method is by using the RS485 start-stop. This is done via MODBUS commands. The limitations of the RS485 are about 1000 meters using a twisted pair cable. This tutorial is about automatic generator auto-start modules. The following matters will be deeply analyzed: automatic generator start and stop wiring diagram, portable generator auto start kit, 2 wire auto start generator, generator self-start kit, low battery auto-start generator, GSM-based automatic start-stop and automatic start generator for home.

CAN A PORTABLE GENERATOR START AUTOMATICALLY?

If your portable generator features an electric start, you can install the Be1 generator auto-start module with two automotive relays. The solution is easy if you follow our instructions. In the case of a gasoline engine, you must install a mechanism to activate the choke.

HOW DO I REMOTE START MY GENERATOR?

The Be1, Be24 and Be124 feature suitable outputs for this task. If your engine is based only on a key start, you may connect pilot relays to drive the fuel-solenoid and start-solenoid. When the engine is running, the controller automatically terminates the crank.

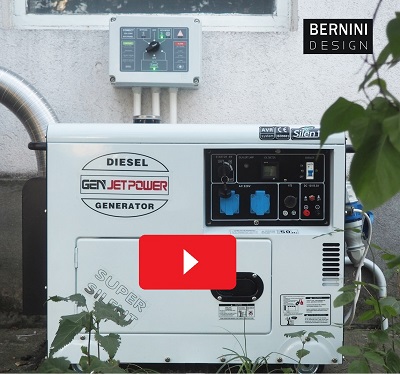

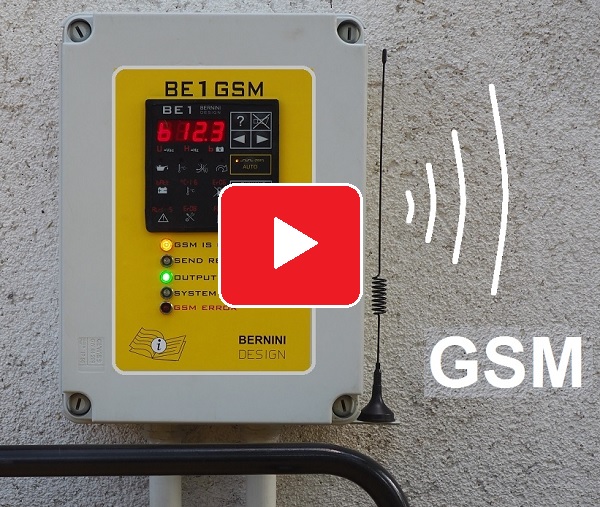

GSM GENERATOR REMOTE AUTO-START PANEL

This generator control panel is based on the Be1 generator controller. This is the best option for small single-phase generators. Id addition to a full remote control via SMS it offers LOw Battery automatic start.

You will find all the details and links for purchasing the panel in the video description.

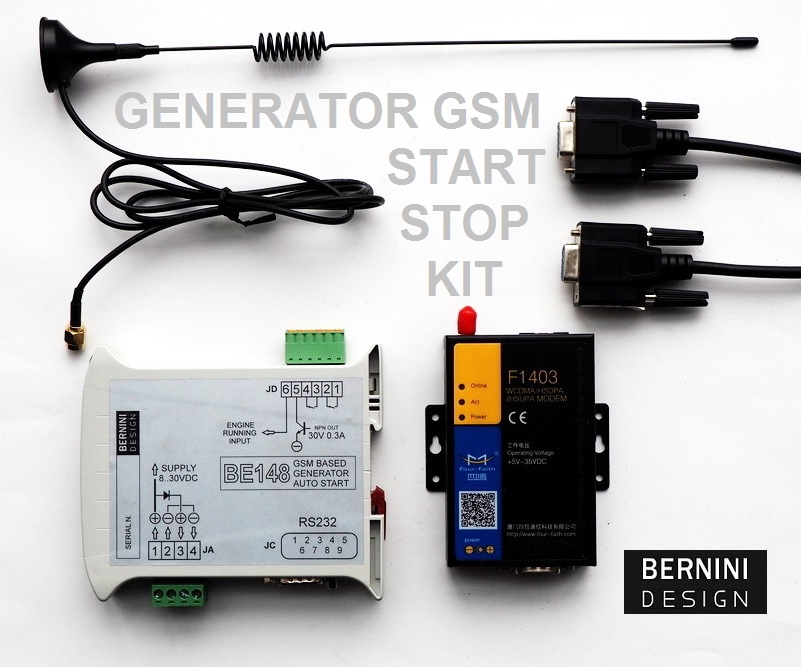

ADDING GSM WITH TO A GENERATOR AUTO-START MODULE

It depends on how reliable your system has to be! We discuss only safe solutions that work 100%. The best way is via GSM. The Be148 GSM kit can start and stop your generator via a single SMS. The SMS is the most reliable way to communicate via GSM. Another method, let us say, via INTERNETt requires complex setups. The Be148 sends an SMS about the engine whether it is running or not. It informs you about the battery voltage. If you like D.I.Y activity, you may add a few relays and you can make a cost-effective GSM-based generator auto-start kit. The best solution is to interface the Be148 with one of our professional auto-start modules like Be24, Be1 or Be124.

HOW DOES ELECTRICAL START WORK ON A GENERATOR?

The principle is similar to your car. A fuel solenoid is energized to allow the fuel to flow. At the same time, the crank motor starts the engine. You release the key when the engine is running. If it is about an auto start module, a special circuit described on thispage will automatically disconnect the starter motor

DO ELECTRIC START GENERATORS HAVE A BATTERY?

Yes, this is mandatory. You are required to carry out the best maintenance you can. This will help you avoid frustrating experiences during a power outage. For this reason, the best option is to provide a low-battery generator auto-start feature. We have all the solutions for you.

GENERATOR AUTO START SWITCH

ALL ABOUT NORMALLY CLOSED OR NORMALLY OPEN CONTACTS IN DRIVING YOUR GENERATOR AUTO START MODULE INPUT

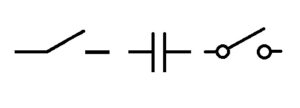

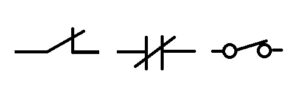

A normally open switch (N.O.) is a switch that is in its open position when you do need to start the generator. When you close the switch, the auto start controller will instruct the engine to start (immediately or after a delay if allowed by the auto start controller). When you open the contact the engine will stop (immediately or after a delay if allowed by the auto start controller).

THIS IS THE NOTATION OF A N.O. SWITCH

A normally closed switch (N.C.) is a switch that is in its closed position when you do need to start the generator. When you open the switch, the auto start controller will instruct the engine to start (immediately or after a delay if allowed by the auto start controller). When you close the contact the engine will stop (immediately or after a delay if allowed by the auto start controller).

THIS IS THE NOTATION OF AN N.C. SWITCH

WHY AND WHEN TO USE N.C. OR N.O. CONTACTS

This is only about safety. In other words, what would happen in the worst scenario: a broken switch, an open connection or a short circuit? You have to consider all issues. You can not start the engine if the cable is disconnected. This could be a serious issue in the case of fire protection systems. But, in the case of open circuits, you can not stop the generator. So the final decision can be made after analyzing all aspects. For normal operations, the N.O. option is the most common choice. Top-level Bernini design generator auto start controllers feature programmable options N.O./N.C. and generator turn-on/turn-off timings up to 24 hours.

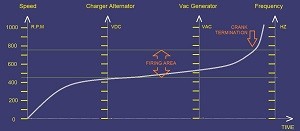

UNDERSTANDING AUTO START CRANK TERMINATION

'Crank Termination' is an adjustable engine speed setting or condition, that shuts down the starter motor when the engine is firing. The cranking must be terminated correctly. This is the most complex function carried out by a generator auto-start controller. The output of the generator auto-start controller drives a pilot relay. When the engine crank termination setting is reached, the pilot relay will stop the current flow to the starter motor circuit. The starter motor pinion gear will disengage from the engine flywheel ring gear. The theory is not so complex. Unfortunately, many ‘volatile’ parameters are involved when you crank an engine: the battery, the ageing of the starter motor, ambient temperature, difficulties in starting the engine due to mechanical problems, unstable connections, and so on. The hard job of the generator auto start controller is to analyze all sources of information to start the engine automatically. It monitors the charger alternator voltage (V), the charger alternator frequency (Hz), the generator alternator voltage (V), the generator alternator frequency (Hz), and the rotational speed of the engine (RPM). For each parameter, the generator auto-start controller features programmable settings including the option 'OFF' (the controller ignores the parameter set to ‘OFF).

The most accurate rotational speed (RPM) information is provided by a pickup. Unfortunately, not all engines have this device. It is about a permanent magnet generator with a single pole. Wire coils are wound around a permanent magnet pole piece. When the teeth of the flywheel ring gear move through the magnetic lines of force, an AC voltage is generated. Engine speed is measured from the pickup frequency. To get the correct rotational speed, you must program the number of teeth of the ring gear. When the generator auto-start controller starts the engine, the software continuously compares the voltage and frequency with your settings. Once one signal is recognized as ‘true’, the controller terminates the crank. The following diagram helps to understand how 'crank termination' works.

BERNINI DESIGN SRL

Industrial Park

46035 OSTIGLIA ITALY

SUPPORT

0039 335 70 77 148