Generator Auto Start Controller

Add two relays to the Be1 generator auto start controller. Get the most from this cost-effective generator controller.

DELIVERY TIME 26 SEPTEMBER

The Be1 generator auto start controller is enclosed in a metal box case with standard DIN 96 dimensions. It features a high luminosity 4-digit display and 6 super-bright LED indicators. This auto-start generator module is suitable for gas, gasoline, and diesel engines. It can directly interface with a flywheel generator or standard belt-driven charger alternator. You can connect any analogue sensor to get Oil Pressure, Engine Temperature, and Fuel Level measurements. Connect a magnetic pickup when you have a DC alternator.

ADJUSTABLE SETTING FOR LOW BATTERY START

By properly setting up the Be1 generator auto start controller you can get the automatic start of the engine when the battery is low.

READ MORE ABOUT LOW-BATTERY AUTO-START

If your generator is placed in a remote location, you can set up an automatic start when the battery is low. This prevents your battery from suffering severe damage from over-discharging.

- Remove the DC supply. Push and hold the button [0], in the same time turn the supply on; hold the button until the message [Lobt] is displayed.

-Simultaneously push [?] and [Auto] to increase the low battery threshold. simultaneously push [?] and [ I ] to decrease the low battery threshold.

- Push the button [→] to select the [Hibt] threshold. Simultaneously push [?] and [Auto] to increase the high battery threshold. simultaneosly push [ ? ] and [ I ] to decrease the high battery threshold.

-To save the settings, simultaneously push [ACK] and [→] for about 5 seconds.

-Enter the programming mode and program an output (example output 4) with the option [15]. You may add a delay before starting and stopping by adjusting the parameters [P0] and [P1] (see Table 7.00). Save your settings by simultaneously pushing the [ACK] and [→] pushbuttons

-Connect the output 4 to the remote input (example input 4)

Can You Control A Generator Remotely?

We recommend that you purchase this auto start controller. It remotely controls your portable generator. You may need to add only two or three automotive relays to interface with the starter, choke and stop solenoid. Purchase the Be1 basic version without RS485 to make a cost-effective portable generator remote start kit. Purchase the GSM option to control the generator from your mobile phone.

BE1 Genertor Auto Start Controller

ONLINE PURCHASE

BE1 GENERATOR AUTO START INSTALLATION MANUAL

PURCHASE ONE SAMPLE

129€

FREE SHIPPING

DELIVERY TIME 26 SEPTEMBER

ASK FOR A QUOTE 2-10-50-100 PIECES BULK ORDER

WhatsApp +40721241361

Gsm +39 335 70 77 148

30-Day Money Back Guarantee And Cancellations

BE1 MODBUS-RTU VERSION

PURCHASE ONE SAMPLE

169€

FREE SHIPPING

DELIVERY TIME 26 SEPTEMBER

DO YOU HAVE MORE QUESTIONS ABOUT GENERATOR AUTO START CONTROLLER IN GENERAL?

YOU CAN FIND ANSWERS TO THE F.A.Q. IN OUR TUTORIAL

Can I Start My Generator From My Phone?

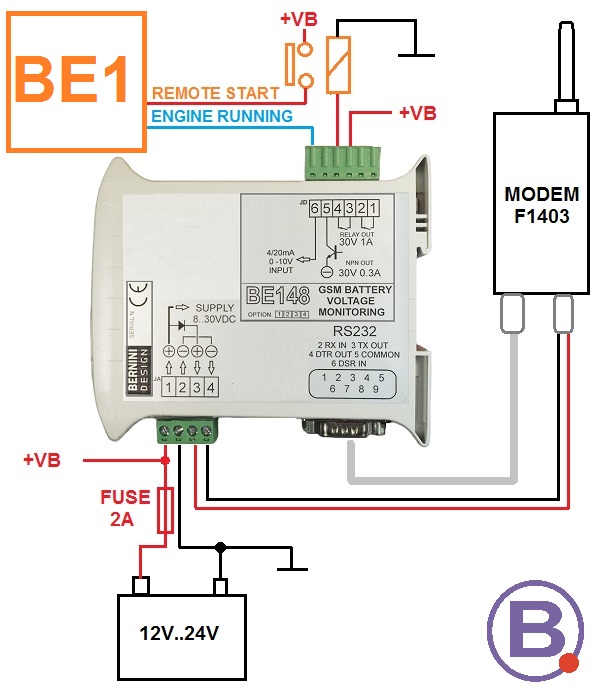

You can control your generator using simple SMS commands by adding the Be148-1 GSM adapter and a Modem. You can find out more details about the functionality on this web page

GSM-BASED GENERATOR MONITORING

This is the typical wiring diagram of a Be1 GSM-BASED generator remote start kit

FREE SHIPPING TO THE EU-US-CANADA

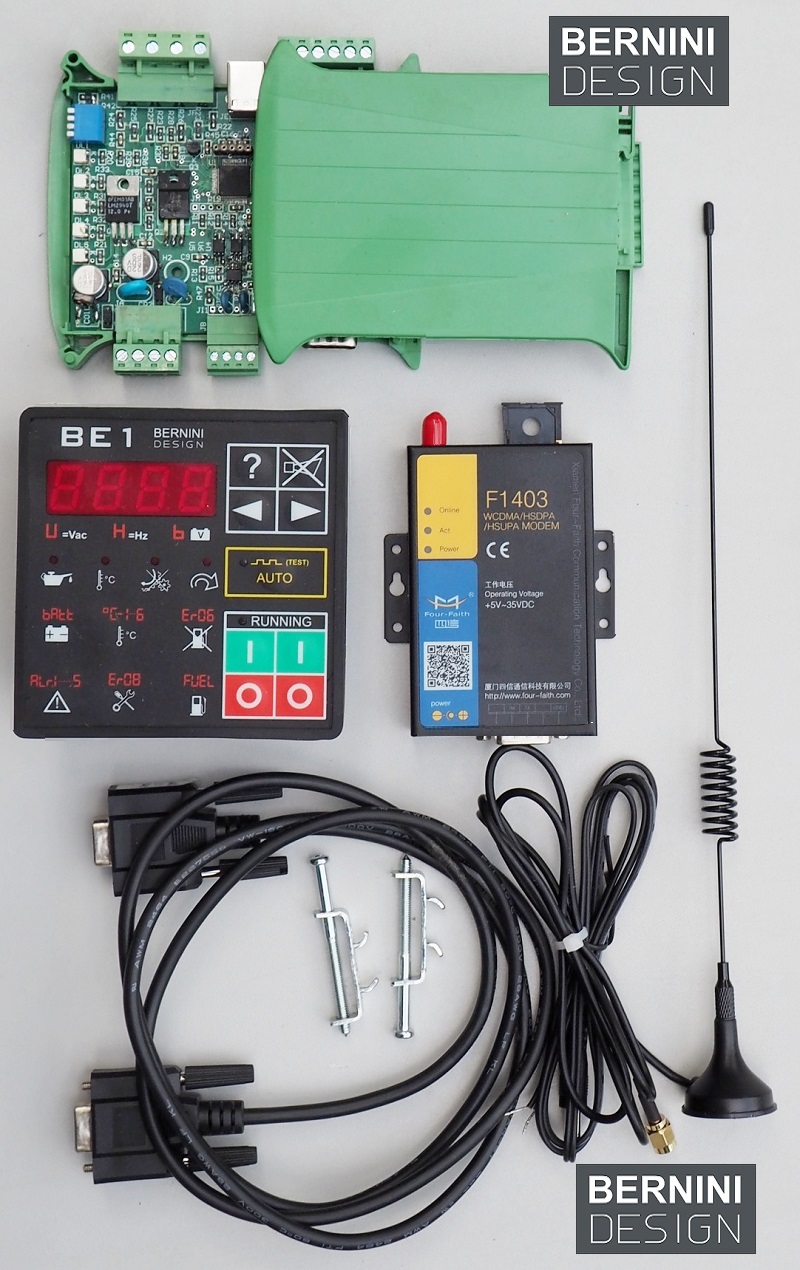

MODBUS-RTU+ BE148 GSM KIT

349€

GET A COMPLETE GSM-BASED MONITORING SYSTEM CONTROL PANEL

This control panel is based on the Be1 auto-start generator controller. It includes all components required to interface with your diesel engine. A complete set of terminal blocks and relays will allow you to set up the system in a few minutes. The MODEM is already included in the panel. You must put a SIM card on it.

FREE SHIPPING TO THE EU-US-CANADA

GENERATOR GSM REMOTE MONITORING PANEL

549€

DELIVERY TIME 26 SEPTEMBER

READ MORE ABOUT THE BE1 GSM-BASED CONTROL PANEL

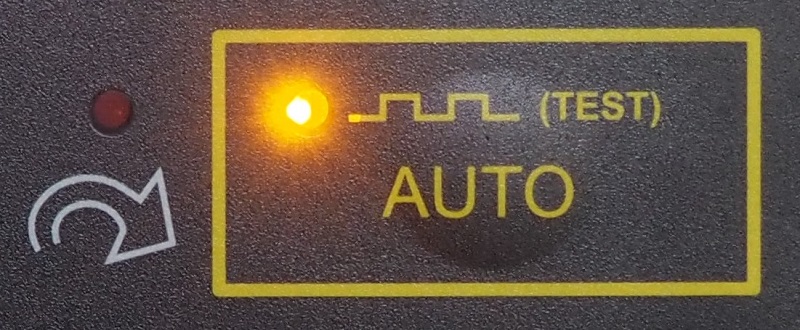

The Be1 auto start generator controller front panel description

The front panel of the Be1 generator auto start is extremely intuitive and thanks to the double set of start-stop buttons, we guarantee the Be1 for at least 2 million start-stop operations. The Be1 is a user-friendly generator AUTO START MODULE and by adding only a few automotive relays you can make an auto-start panel. You can connect analogue or digital sensors.

You can use Be1 to refurbish the control panel of a gas, gasoline, or diesel engine. The RS485 serial interface supports the MODBUS protocol and the software is free of charge. Thanks to the high-quality gasket the Be1 features IP54 ingress protection. The START/STOP pushbuttons are redundant and you can expect a long life even in harsh environments.

The avionics-grade' display and LED indicators will offer full visibility between -30 to 70 degrees Celsius.

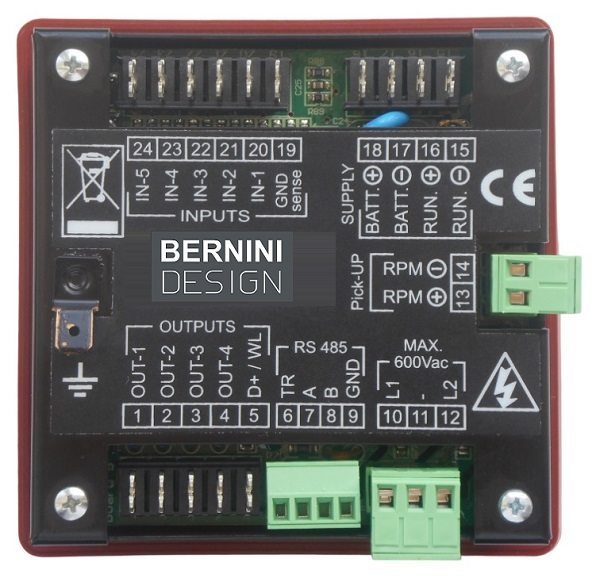

Generator auto start controller connections tutorial

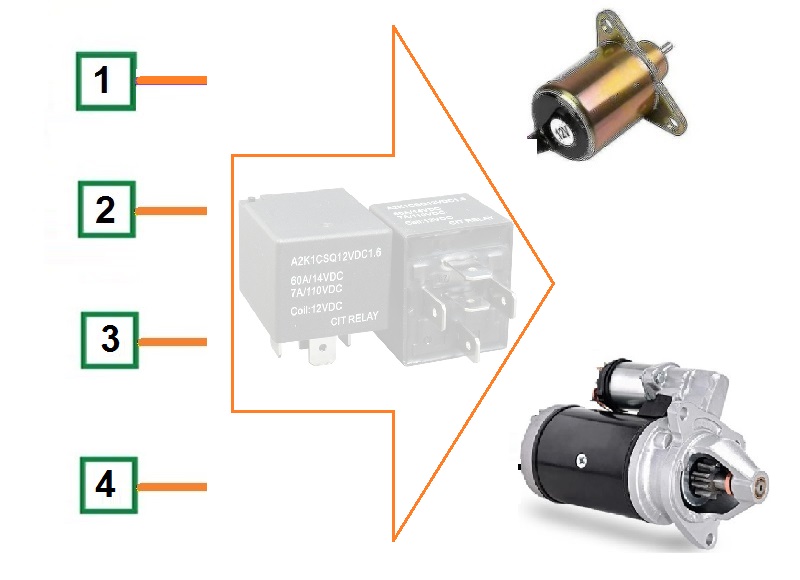

The Be1 is the perfect choice for a gasoline generator. It interfaces with the Flywheel generator to trigger a crank termination. The Be1 offers two options to stop the gasoline engine: STOP SOLENOID or FUEL SOLENOID.

This output energizes when you want to stop the engine. The contact of the relay will close to ground the ignition terminal on the spark generator remote start. You can easily find this terminal because it is normally connected to the STOP switch on the body of the gasoline generator. The engine stops when the spark plug is off. You can adjust the time for STOP SOLENOID. You can also use the FUEL SOLENOID by connecting a relay to the output [1]. The engine runs only when the FUEL SOLENOID output is active. This is an 'ENERGIZED TO RUN' output. The best solution is to use both: STOP SOLENOID & FUEL SOLENOID. The start circuit is quite similar to a diesel engine. Finally, connect the starter pilot relay to the output [2].

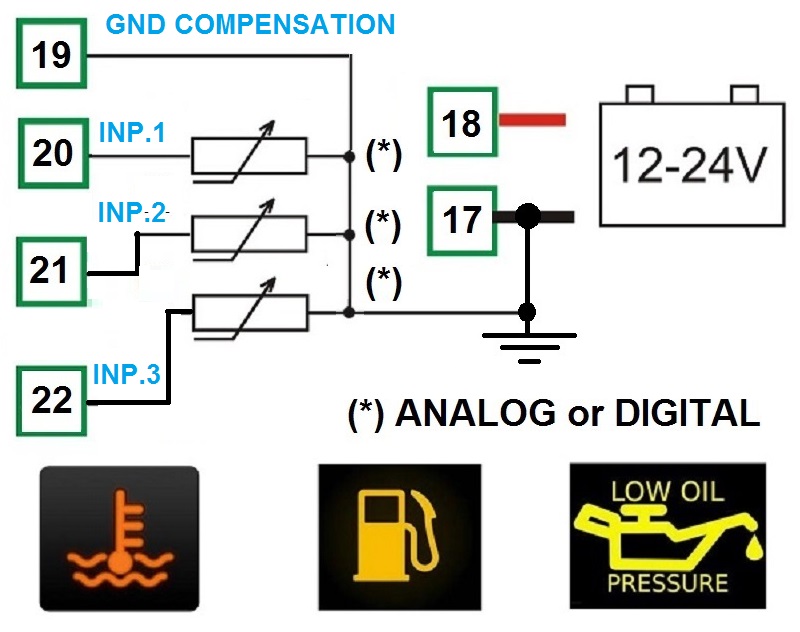

INPUT CONNECTIONS and POWER SUPPLY

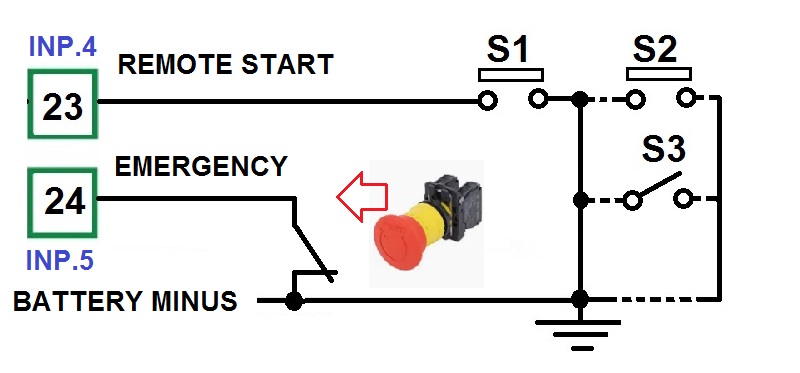

Even though all inputs are freely programmable in digital or analogue mode, the Be1 is supplied with factory defaults. The input [4] is set for remote start input in normally closed mode. Connect all switches committed to starting the engine in a logical OR. When at least one input is connected to the ground, the Be1 will instruct the engine to start. When all input switches are open,t the Be1 will instruct the engine to stop.

The input [5] is set as normally closed contact. It will trigger the emergency alarm. This input is reserved for the emergency button. All inputs when set in digital mode, only accept dry contacts. It must be isolated from an external source of voltage.

The default programming for INPUT [1] is OIL PRESSURE SWITCH, for INPUT [2] is FUEL LEVEL SWITCH, and for INPUT [3] is ENGINE TEMERATURE SWITCH. Connect dry contact only. Configure the inputs into analogue mode if the engine features analogue sensors. For each input, you can program a 5-point response curve. The power supply must be connected to terminals [17] and [18]. We recommend that you protect the wires with 4 Amps FUSE. The Be1 controller has it own electronic fuse of about 500mA. The Be1 accept 12V or 24V batteries.

OUTPUT CONNECTIONS

The Be1 offers four programmable outputs. Each output can be associated with one of the 31 available options. Default programming sets the output for the most common applications, such as fuel solenoid, start, and pre-glow. The outputs are short circuit proof, the logic is negative. The output is designed to drive automotive relays. In other words, you must connect the other side of the relay coil to the battery plus. To avoid electrical noise we always recommend that you use the flywheel diodes.

RS485 CONNECTION

The RS485 supports the MODBUS protocol. You can monitor the engine, control the alarms, open the Event History, program the Module, and save the programming using a normal computer.

THE BE1 GENERATOR AUTO START MODBUS PROTOCOL

You can extend the RS485 cable up to 1000m. On the same bus, you can connect as many as 24 controllers. We offer solutions for remote monitoring via TCP-IP and GSM.

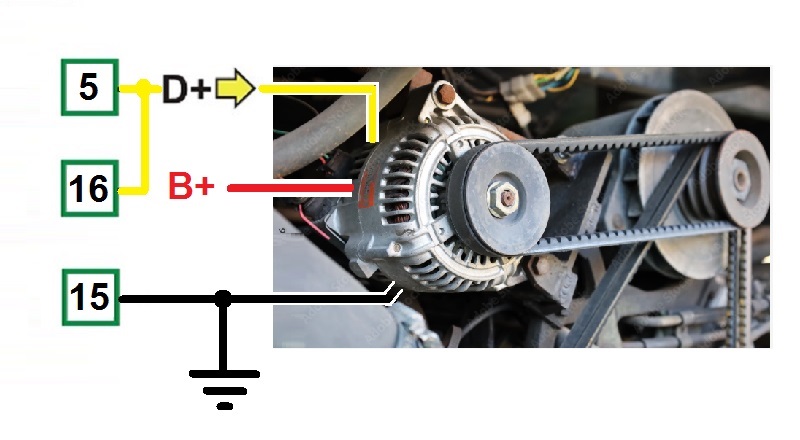

CHARGING ALTERNATOR CONNECTIONS

If you can not connect the flywheel generator, the Be1 features adjustable settings to terminate the crank from the Voltage and frequency of the GENERATOR. You can also connect a pickup to get an accurate reading of the rotational speed. Also in this case do not worry about it. The Be1 can calculate the RPM from the alternator frequency. You only have to set up the number of poles of the alternator. The connection for sensors, analogue or digital, is indicated in the wiring diagram.

BELT ALTERNATOR

The terminal [5] supplies excitement current to the alternator. Terminal [15] must be connected to battery minus.

BELT ALTERNATOR MONITORING

The auto-start generator module automatically terminates the crank when the engine starts running. The Be1 provides an exciting current for the charger alternator. When the engine is not running, the voltage of the terminal D+/WL is 0V (in your car, before starting the engine, the red 'DYNAMO LAMP' turns on).

As soon as the Be1 controller starts the engine, a voltage appears in the D+/WL terminal and when the engine runs normally, the voltage of the D+/WL terminal increases by up to 13-14 V (in your car, having one side of the lamp connected to the battery plus, the red 'DYNAMO LAMP' in the dashboard turns off ). The safest point to terminate the crank is between 6V to 10V.

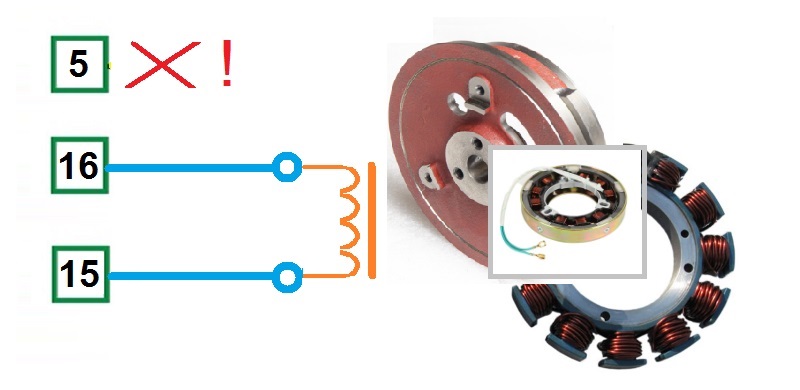

FLOATING ALTERNATOR

This is the typical connection for a gasoline engine or a 3000RPM small diesel generator. The wires are floating. For this reason, you must not connect the terminal [5]. The principle of detecting an engine's running status is similar to a belt alternator.

The display indicates the average voltage supplied by the flywheel alternator when the engine runs at a nominal rotational speed.

BE1 GENERATOR REMOTE START INSTALLATION MANUAL

ELECTRICAL CHARACTERISTICS

Battery supply voltage: 5.5Vdc to 36Vdc. Supply current: 10 mA to 80 mA.

Inputs: digital (switch) or analogue (0-1000 OHM).

Dimensions: 96X96X 47(mm). Panel Cut-out: 91mm X 91mm.

Ingress protection: IP65. Outputs: 300mA, NPN short circuit proof.

Operating temperature range: -30 deg C up to +70 deg C.

Humidity range: 5% up to 95% non-condensing.

Weight: 350 gr., Vibration: 40mm/sec.

Pick-up Input: Voltage input: 2 - 60Vac; 0-10KHz

Generator Monitoring: Operating up to 600Vac.

Accuracy: +/- 1,5%. Frequency: 20-70Hz

BE1 MANUAL MODE

A) - Push one of the [ I ] push buttons until the display indicates the message [MAn] and all LEDs illuminate; release the button.

B) - Push one of the [ I ] push buttons until the engine starts. When the engine runs, the green LED 'START-ON' will illuminate.

C) - To stop the engine, push the [ O ] push button until the [StOP] message appears on display.

If the engine has already stopped, it is possible to cancel the STOP sequence by pressing the [ O ] push button. Push [ O ] when the engine is not running if you want to shut down the panel.

GENERATOR REMOTE START: THE AUTO MODE

Push the [AUTO] push button until the yellow LED 'AUTO' on the button illuminates. The engine starts when you activate the input configured as 'Generator Remote Start Input'. Deactivate the 'Generator Remote Start input' to stop the engine. In the AUTO mode of operation, the Be-1 will periodically test the engine if you properly programmed the scheduler or the so-called 'Periodic Auto Start'. During this test, the yellow LED AUTO will continue to blink.

The Be1 controller can start the engine when the battery is low only in Auto mode. You must set the low battery voltage threshold and high battery voltage stop threshold. After configuring the output, you must connect this output to the remote start input.

The AUTO mode of operation is stored in a 'NON VOLATILE MEMORY'. If you remove and re-apply the DC supply, the Be1 will automatically enter the AUTO mode of operation.

To exit the AUTO mode of operation, push, for a short time, the [AUTO] push-button. The Be1 will enter the MANUAL mode of operation. You can directly push one of the [0] push buttons. In this case, the Be1 will directly enter the OFF mode of operation.

Be1 ALARM MONITORING

The Be1 auto-start generator kit features Shutdowns (the engine stops) and Warnings (the engine will continue to run). It informs you about an alarm via:

A) - a general indication of alarm using the message [ALAr.] on the display

B) - 4 configurable outputs with several options for each

C) - 4 LEDs indicating Oil pressure, Temperature, Failure to start, and Over-speed shutdown.

D) - coded display messages about warnings and shutdowns

E) - a [ACK] push button to silence the Horn

To browse the alarm memory push the [→] pushbutton. To display the details of the alarm, push the [? ] push button. To clear the alarm from the panel, remove the cause of the alarm and then press the [ O ] push button.

The Be1 HISTORY LOG

This auto-start kit features an Event History memory of the last 100 shutdowns. To read the contents of the Event History, follow the instructions:

A) – Remove the DC power supply (battery voltage)

B) – Push and hold the [?] pushbutton

C) – Apply the power supply (holding the [?] pushbutton)

D) – Release the [?] pushbutton when the display turns on

E) – The display will indicate the last event via the message [E 01]. Push the [?] push button to display the name of the Event (see table 4.10 in the installation manual)

F) – You can select [E 01] (the last event) up to [E100] (the oldest event) using the [←] and [→] push buttons.

G) – To display the code of the Event, push the [?] pushbutton (see table 4.10 in the installation manual).

It is not possible to cancel the Event History. You are required to cancel all memory (see instructions in the installation manual)

BERNINI DESIGN SRL

Zona Industriale

46035

Ostiglia Italy

+393357077148