BE126 NFPA 20 FIRE PUMP CONTROLLER

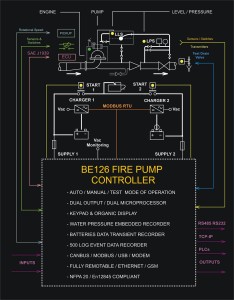

Bernini Design is specialized in manufacturing NFPA 20 compliant controllers. The BE126 is a combined NFPA 20 fire pump controller and automatic and manual diesel engine fire fighting system controller.

The BE126 is a multiprocessor automatic and manual diesel engine fire fighting system controller. It meets or exceeds the requirements of NFPA 20 NFPA 20 & UNI 12845 standards. All Accessory devices, such as fire pump alarms and signaling means, are included in Be126. Finally, this ensures maximum performance of the equipment that you are going to make using the Be126 diesel engine fire pump controller. In conclusion, the Be126 fire fighting system controller is suitable for use in locations subject to a high degree of moisture, such as a damp basement or others.

BE126 KEY FEATURES

BE126 NFPA20 INSTALLATION MANUAL

Bernini Design is specialized in the design and manufacture of diesel engine fire fighting system controller NFPA20 compliant

DISPLAYS VOLTAGE & CURRENT OF THE TWO BATTERIES

FIVE INDEPENDENT DISPLAYS LEDs+ GRAPHIC 128x64

ORGANIC GRAPHIC DISPLAY WORKING -30°C UP TO +70°C

MONITORS UTILITY POWER V-HZ-SEQUENCE & OTHERS

BATTERY, PUMP, MAINS & ENGINE INSTRUMENTS

GSM ALARM ALERTS WITH TIME STAMP

REDUNDANT MEMORY SYSTEM WITH 200 LOG EVENTS

EMBEDDED WATER PRESSURE 30-DAY DATA LOGGER

ACCEPTS DIGITAL AND ANALOG PRESSURE TRANSMITTER

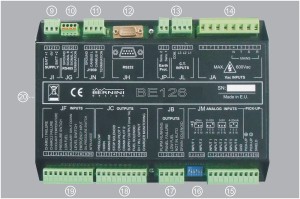

FEATURES RS485, RS232, CANbus (SAE J1939 COMPATIBLE)

PURCHASE A BE126

FREE SHIPPING

949€

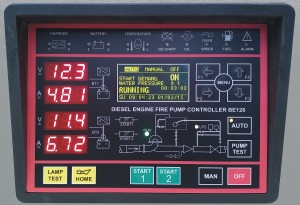

THE BE126 FRONT FASCIA

[1] ALARMS PANEL [2] GRAPHIC DISPLAY [3] NAVIGATION PUSH BUTTONS [4] MENU PUSH BUTTON [5] AUTO PUSH BUTTON [6] TEST THE PUSH BUTTON[7] OFF PUSH BUTTON [8] MAN PUSH THE BUTTON [9] PRESSURE INDICATOR [10] START PUSH BUTTONS [11] ENGINE RUNNING LED [12] START PILOT RELAYS [13] HOME BUTTON [14] LAMP TEST & ALARM SILENCE [15]-[16] [17]-[18] BATTERY 1 INSTRUMENTS

BE126 NFPA 20 FIRE PUMP CONTROLLER MODES OF OPERATION

[MANUAL MODE]

Push the [MAN] until the external lamp 'NOT IN AUTO' turns on. In order to test the integrity of the batteries, program the option 'FUEL DISABLED'. Push and hold the [START 1] button for at least 30 seconds and watch the stability of the battery voltage. If the Be126 will detect a faulty battery, the display will provide full information. Do the same with battery 2 ([START2]). You can enable the fuel and start manually the engine using start 1 or 2. When the engine is running, the green LED will turn on. You can browse the engine instruments by using the navigation pushbuttons.

[AUTO MODE]

Push the [AUTO] mode push button. To test the system pushes the [PUMP TEST] button. The Be126 will automatically open the drain valve. The LOW-PRESSURE SWITCH will trigger the start of the engine and will turn on the YELLOW LOW-PRESSURE LED INDICATOR. Follow the menu-driven instructions on the display in a way to carry out the full test according to NFPA 20 (or UNI EN 12845) requirements. After completing the test the BE126 will enter the AUTO mode of operation automatically. In case of a problem, the display will provide you with all information

NFPA 20 FIRE PUMP CONTROLLER SYSTEM OVERVIEW

The Be126 Fire Pump Controllers from Bernini Design are designed to control and monitor 12 or 24 volts, diesel fire pump engines used in NFPA 20 or UNI-EN 12845 compliant fire fighting applications. Firstly, the Be126 is among the most technically advanced diesel engine controllers available on the market today. Secondly, the Be126 features a state-of-art multiprocessor structure providing an embedded water pressure data logger capable of storing up to 31 days of data recording. Thirdly, the Be126 interfaces with standard diesel engines or SAE J1939 compatible engines. Additionally, the Be126 fire pump controller monitors, displays, and records fire pump system information also. The Be126 diesel engine fire pump controller is designed to start the diesel engine automatically from water pressure control or non-automatically from manual electric control. Furthermore, this type of diesel engine fire pump controller maintains the full charge on engine starting batteries, monitors engine and system conditions, and initiates a weekly program test of the system. Be126 monitors analog or digital water pressure or water level transducers. Be126 is able to provide mathematical calculations over the pressure, providing MIN, MAX, and AVG values. By enabling the Engine Protection Mode software you can use the Be126 controller on a standard diesel engine pump water station. In conclusion, the Be126 controller features RS232 and RS485 serial interfaces that provide ASCII and MODBUS protocols. By using our TCP-IP server, you can connect the Be126 to the Internet.

The Reliability of operation for this fire fighting system controller is not be adversely affected by dust accumulations, variation of temperature, humidity, fungus, or adverse elements. The BE126 is extremely strong and insensitive to vibrations. The basic structure is made of steel and carbon fiber. A NEMA Type 2 drip-proof is provided with IP54 ingress protection.

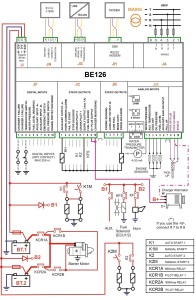

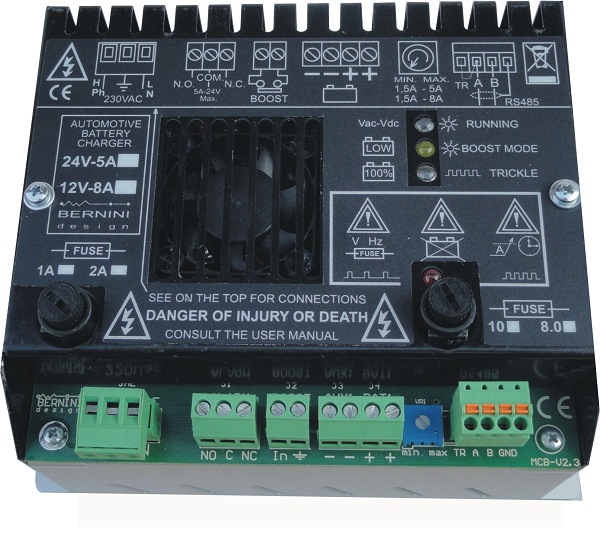

TO COMPLY WITH NFPA20 THE CONTROLLER MUST DISPLAY THE VOLTAGE AND CURRENT OF EACH BATTERY. BY USING THE MCBXX BATTERY CHARGER, THE BE126 READS THE CHARGING CURRENT VIA RS485-MODBUS.

NFPA 20 TYPICAL WIRING DIAGRAM

MODBUS BASED NFPA20

BATTERY CHARGERS

MCB 12-24V USER MANUAL

- MODBUS via RS485, Alarm Relay (dry contacts)

- Operating Temperature Range: -30/+70 deg. Celsius

- Current limited, it will only output the rated current

- Boost Mode push button, Current setting via Trimpot

The MCB family of automatic intelligent battery chargers is designed for industrial-automotive applications in harsh environments. Utilizing high-performance components and corrosion-resistant anodized aluminum housing, it allows you to build a reliable control panel for standby generators. The MCB is a microcontroller-based, intelligent battery charger, ideal for NFPA110 & NFPA20 applications. The MCB complies fully with UL1236 and NFPA-20 regulations.

MCB 12V 8A SHIPPING

299€/each

KEY FEATURES

- Microprocessor-based, 4 LEDs indicators

- Removable connectors (M/F) & two fuses on the front

- Designed for over 20 years of continuous service

- Over-Voltage/Current, Over-Temperature protections

- Ideal for industrial NFPA 20 panels

- Boost charge time out, fault Battery detection

- Complies with DIN41773, Reverse Battery Protection

BERNINI DESIGN SRL

ZONA INDUSTRIALE

OSTIGLIA - ITALY

[email protected]

+39 335 70 77 148