WHAT IS ATS CONTROLLER?

It is an electronic module committed to controlling the transfer of a LOAD from Mains to Generator and vice versa. The ATS controller automatically or manually manages and drives the connection assignment of the LOAD to MAINS or GENERATOR.

WHY TO USE THE BE242 CONTROLLER?

A traditional ATS controller needs as many meters of cables, many connections and accessories. The Be242 ATS controller is made of two parts. You will change the way to make an ATS panel. On the backplane, you install the ATS controller relay board. It will be easy to connect any kind of engine. You will benefit from the following features

FUEL SOLENOID RELAY

STOP SOLENOID RELAY

START SOLENOID RELAY

2 CONFIGURABLE RELAYS

6 CONFIGURABLE DIGITAL INPUTS

3-PHASE 600V INPUT GENERATOR

3-PHASE 600V INPUT MAINS

8Amp KM DRIVE RELAY

8Amp KM DRIVE RELAY

3X5Amp CT INPUTS

2XFUSES FOR THE COILS

BELT ALTERNATOR I/O MONITOR

We design state-of-the-art ATS CONTROLLERS so you can make professional products. By installing the ATS controller on the front of the cabinet, you must cut out a round hole and 4 small holes. This is 10 minutes job. This ATS controller contains all the electronic circuits you need.

USE THE BE242 ATS CONTROLLER TO SAVE METERS OF CABLE

THE BE242 ATS CONTROLLER DOES NOT NEED A SQUARE HOLE

MAKE A SIMPLE ROUND HOLE!

THE BE242 DOES NOT NEED RELAYS

FIRST IN THE WORLD 20mm-THICK ATS CONTROLLER

You will fix the controller on the door of the ATS panel by making 4 holes. You will make a round hole for the interconnection cable, supplied by us. No square hole is required. It is a 5-minute job. The ATS controller will benefit from the shield effect created by the plate of the metal door.

ATS CONTROLLER INSTALLATION MANUAL

You will connect the generator and the engine start-stop circuits to the relay interface module.

You are no longer required to wire connections to the rear door panel. The relay board includes auxiliary relays and short-circuit-proof components. To make a professional Automatic Transfer Switch panel, you only require a metal or plastic cabinet, battery charger, current transformers, and contactors. You can choose the best solution by using the configurable INPUT-OUTPUT options.

ATS CONTROLLER PRICE

299€

FREE SHIPPING WORLDWIDE

3-EAR WARRANTY

SUPPORT (GMT+1) +39 335 70 77148

CONTACT US [email protected]

ATS CONTROLLER PRICE

2 SET OFFER

199€ / each

FREE SHIPPING TO EU US CANADA

3-YEAR WARRANTY

ATS CONTROLLER PRICE

4 SET OFFER

159€ / each

FREE SHIPPING TO EU-US-CANADA

3-YEAR WARRANTY

Despite its square shape, the ATS controller needs only a round hole for the interconnection cable and emergency switch.

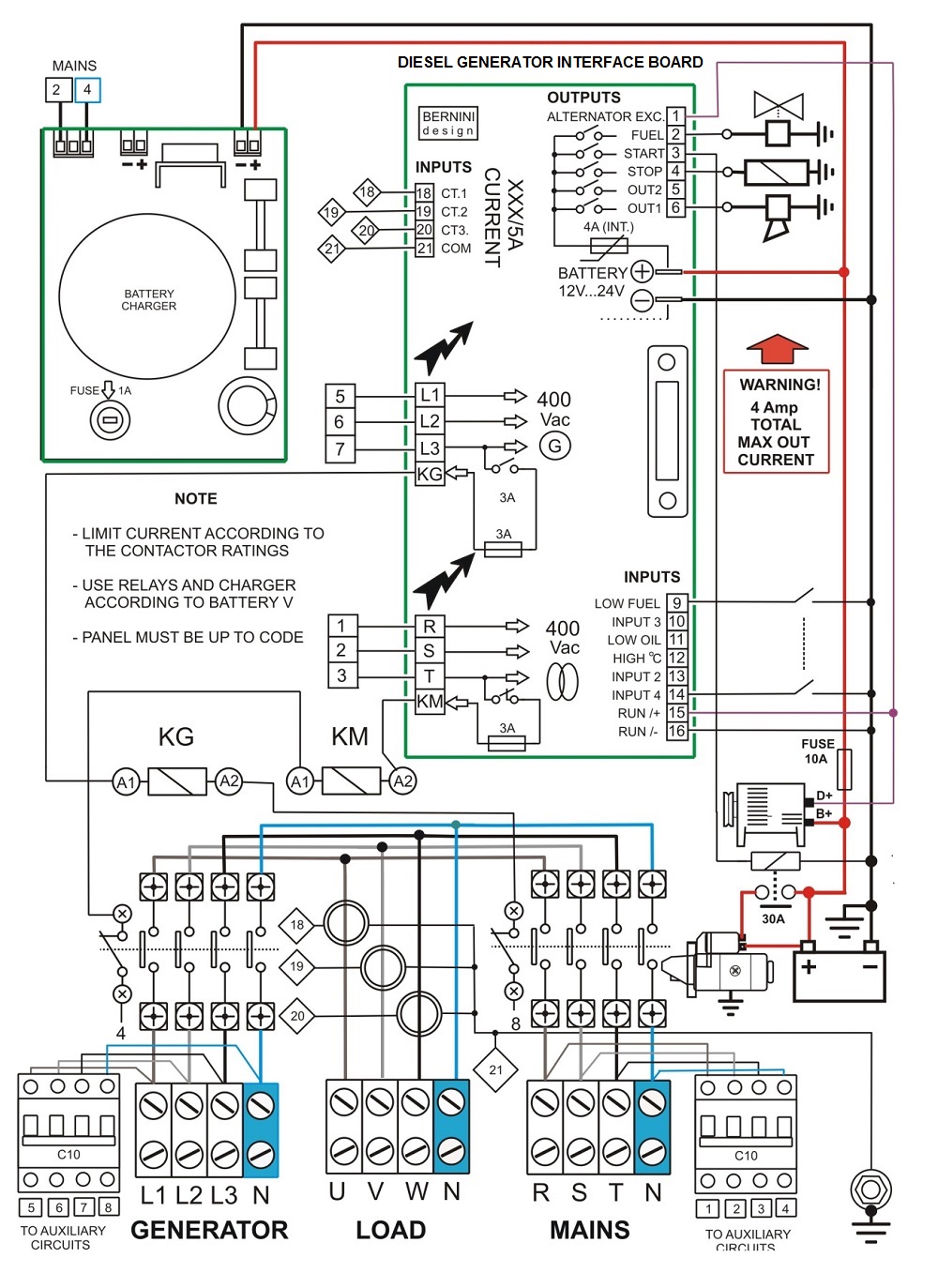

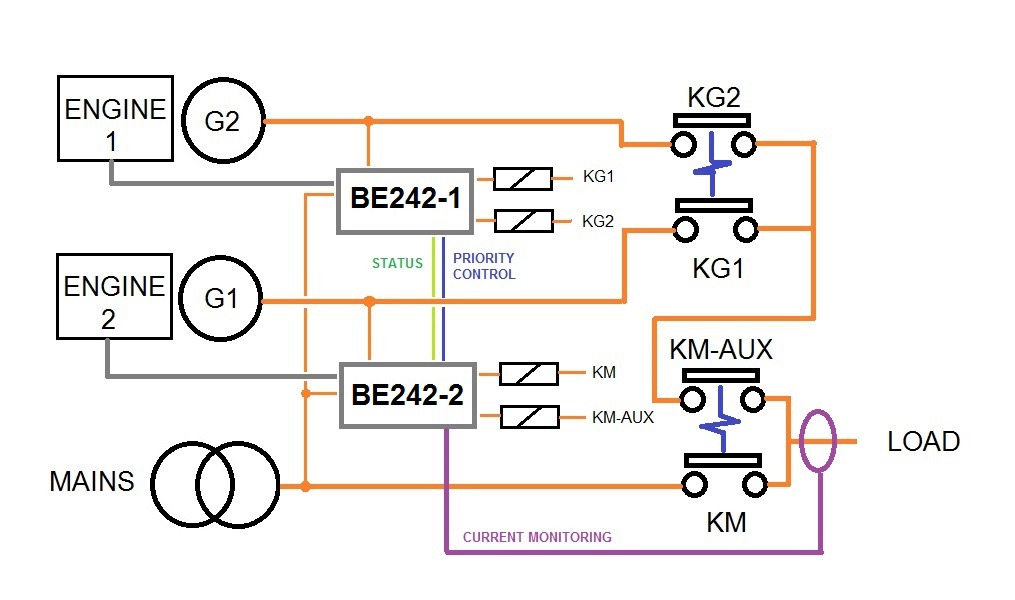

TYPICAL ATS PANEL WIRING DIAGRAM

GENERATOR-LOAD The generator is electrically connected to the LOAD via the KG (contactor of the generator). This is possible only when KM is open. The KM-AUX are the auxiliary contacts fitted on the body of the KM. When the KM is open, the auxiliary contacts are closed in a way to enable the KG. The BE242 energizes the coil of the KG by supplying voltage to the terminal KG. The other side of the coil is connected to the neutral via the auxiliary contacts. When switching the Generator to Power Utility the user may observe a short ‘power outage’. Normally it is about 2 seconds. This is the typical behaviour of the automatic transfer switch: BREAK-BEFORE-MAKE. This is a way to protect the appliances from overcurrents.

To get the KG closed you need KM-AUX and KGC closed

UTILITY POWER-LOAD The utility power is connected to the LOAD via the KM contactor. The coil of the KM is energized by the output KM of the ATS controller. When the KG is open, it closes its auxiliary contacts. This provides a neutral to the other side of the KM coil. Inside the BE242 REALY BOARD, the relays that drive the KM output feature normally close contacts. By doing so, the ATS controller gives priority to UTILITY POWER in case the ATS controller is damaged or without supply. If we use the normally open contacts, all the time we remove the DC supply or we remove the battery of the engine, we disable the contactor of the mains. The user will get an unexpected power failure in the building even if the UTILITY POWER is healthy. This is why we use the normally closed contacts. In case of real power failure, the ATS controller energizes the KM. This prevents the panel from supplying the LOAD with improper electrical parameters. Once the KM is open, the auxiliary contacts KM will close. This is one of the mandatory conditions to close the KG (the KM must be open in the first place).

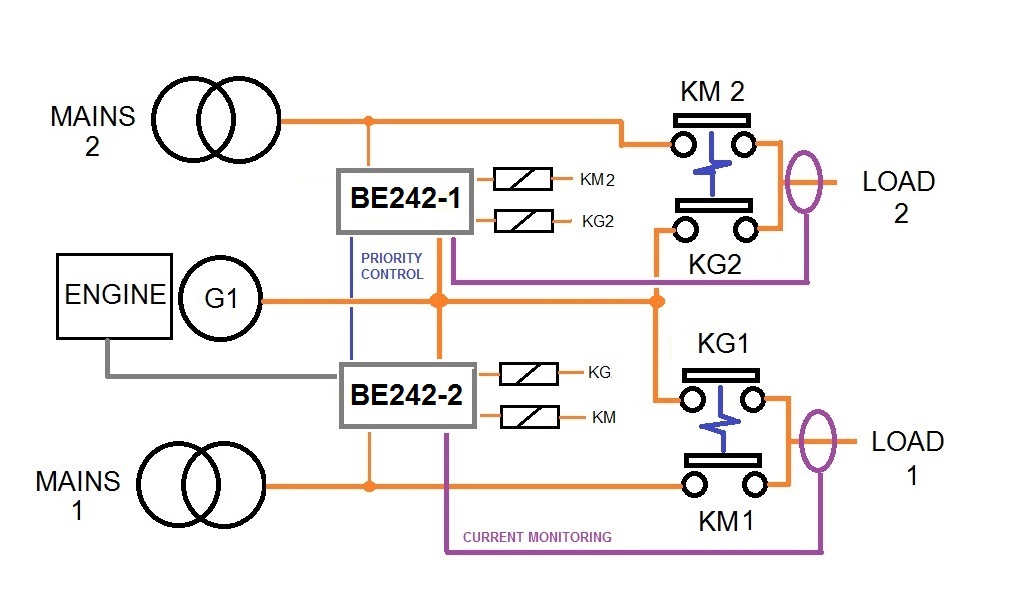

ATS CONTROLLER IN A DUAL LOAD SYSTEM

The following wiring diagram presents the basic connections of a dual-load ATS controller configuration.

By using the Be242, you can use one generator capable of serving two separate loads. The generator will supply the load that is affected by a mains failure. This application is typical in private houses. By purchasing one generator you can solve the power outage issues for two houses. You need to make to ATS panel of a suitable size.

ATS CONTROLLER IN A DUAL GENERATOR SYSTEM

The following wiring diagram presents the basic connections of a dual-generator ATS controller configuration. With Be242 you can connect two generators as an emergency standby to one single load. The BREAK-BEFORE-MAKE configuration is mandatory for the protection of the load. In case of a prolonged mains failure, you can set up ENGINE 1 as a master. In case of starting failure, the second engine will start. The generator will supply the load. You are required to include the ATS controllers and transfer switches in the same cabinet.

SETTING UP THE ATS CONTROLLER

The Be242 is user-friendly. The installation manual will help you in making the panel. The ATS controller is delivered with default settings for 400V 3-phase and diesel engines. You can program the ATS controller on-site in a few minutes. You can arrange a dual-set configuration or dual-load configuration. The Be242 accepts single or tri-phase ALTERNATING voltage connected to the mains and generator. You can choose configurations single-phase or tri-phase for generator and mains. To drive the motor of the transfer switch connect the KM and KG outputs as indicated in the wiring diagram. Use the battery of the engine to supply the ATS controller. You can use the Be242 controller for up to 1000kVA electrical system.

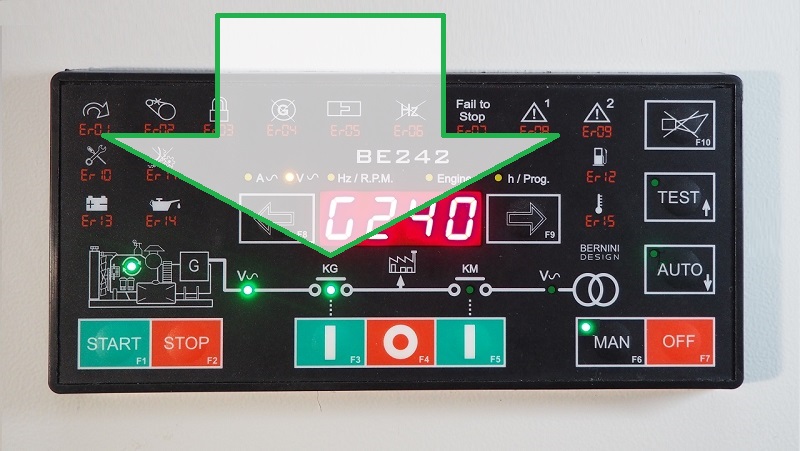

HOW TO USE THE BE242

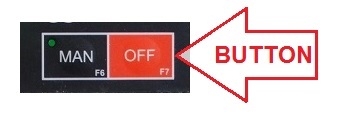

OFF-MODE OF OPERATION

Push the button [OFF] of the ATS controller to enter the OFF mode. The OFF mode clears the fault alarms and allows you to read or program parameters.

The Display and LEDs are turned off and a dot on the display will blink slowly. Push one of the pushbuttons on the front panel to energize the display.

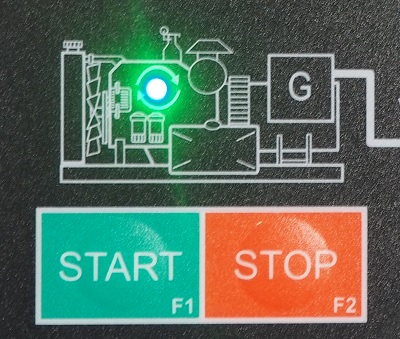

MANUAL MODE: STARTING THE ENGINE

The MANUAL mode allows manual control of the engine and circuit breakers. Push the [MAN] push button to select the MANUAL mode. Push the [START] push button of the ATS controller until the engine starts; the display indicates the message [. . . .] during the starting attempts or [! ! ! !] if preheat has been programmed.

When the engine is running, the green LED turns on.

To stop the engine, push the [STOP] push button of the ATS controller until the [StOP] message appears on the display. If the engine has already stopped, it is possible to reset the STOP sequence by pressing the [STOP] push button.

MANUAL CHANGEOVER

Select the MANUAL mode, start the engine and wait for voltage presence. Push the [ I ] (KG) push button of the ATS controller to close the Generator circuit breaker.

To transfer the Load to Mains, push the [I] (KM) push button (the [KG] will open). To open a Contactor, push the [O] push button of the BE242 controller. In manual mode, the CHANGEOVER timer lasts one second.

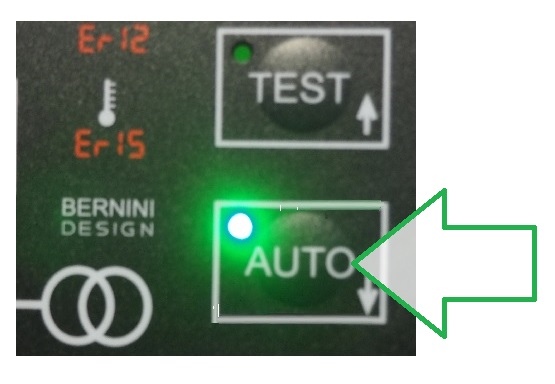

ATS CONTROLLER AUTO MODE OF OPERATION

Push the [AUTO] push button of the ATS controller until the green LED illuminates. The engine starts when the Be242 detects a Mains failure. The Contactor of the MAINS (KM) opens after the BREAKER timing. After the warm-up time, if the voltage and frequency are within the settings, the circuit breaker of the generator (KG) will close.

If the Mains restores, the KG will open. The KM will close following a programmed changeover timing. The Engine will stop after cooling downtime. If the engine shuts down, the KM closes independently of the Mains status if the [P.48] is [ON] (NFPA-110 mode), otherwise, the KM will close only if the Mains is within programmed settings. In AUTO mode, the BE242 will periodically test the engine if the parameters [P.41] and [P.42] have been programmed. During this test, the green LED of the AUTO mode will continue to blink. In AUTO mode, the Be242 can start and stop the engine according to programmed inputs.

ATS CONTROLLER TEST MODE OF OPERATION

Push the [TEST] push button of the ATS controller until the green LED illuminates. The Be242 ATS controller starts the engine and transfers the load to the Generator if [P.17] is [on]. To stop the engine, select the AUTO mode (if Mains is present) or select the OFF mode. If you push the [STOP] push button when the ATS controller is in AUTO or TEST, the [Er.09] will energize. To clear the alarm, select the OFF mode.

ATS CONTROLLER SPECIFICATIONS

DC Supply: 5.5/30Vdc, 50/150mA

Protection: 500mA thermal fuse

Dimensions: 194 X 146 X 205

Panel Cut-out: Round 60mm

Operating temperature: -30 to +70 deg C

Humidity range: 8% up to 90%

Weight: 300 grams

Meets ECC 89/336, 89/392, 73/23, 93/68, IEC 68-2-6

Certification: CE

Display: 4 digits solid state

LED Indicators for all functions

12 Silver-Membrane-Type 100.000 actions life

Over 60 programmable adjustable settings

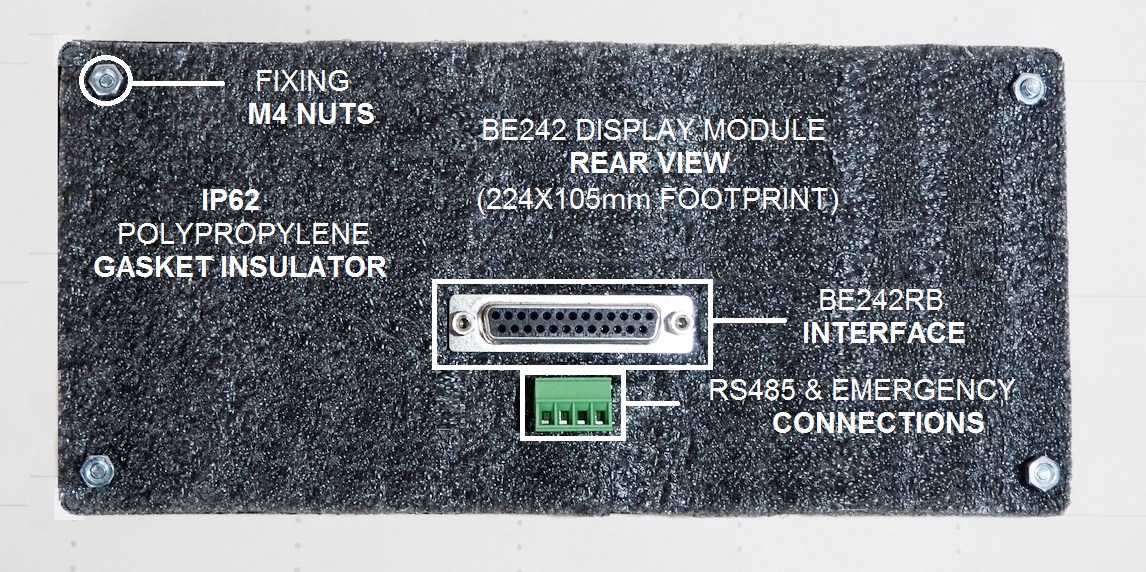

THE ATS CONTROLLER RELAY BOARD INTERFACE

Supply Voltage: 5.5-30Vdc, 50-150mA

Protection: internal 3A thermal fuse

Dimensions: 210 X 150 X 80 (mm)

Installation: DIN-RAIL

Temperature: -30 deg C up to +70 deg C.

Humidity: 5% up to 90%

Weight: 600 grams

Metts ECC 89/336, 89/392, 73/23, 93/68.

Certification: CE

DC Relay Outputs: 3A 30VDC.

AC Relay Outputs: 8A 250V AC

Output Fuses: 2A

Connectors: removable terminal blocks

Operating Vac: up to 600Vac

Overvoltage Voltage: 2KVac

CTs: up to 1000/5Aac

HOW DO YOU MAKE AN ATS PANEL USING AN ATS CONTROLLER?

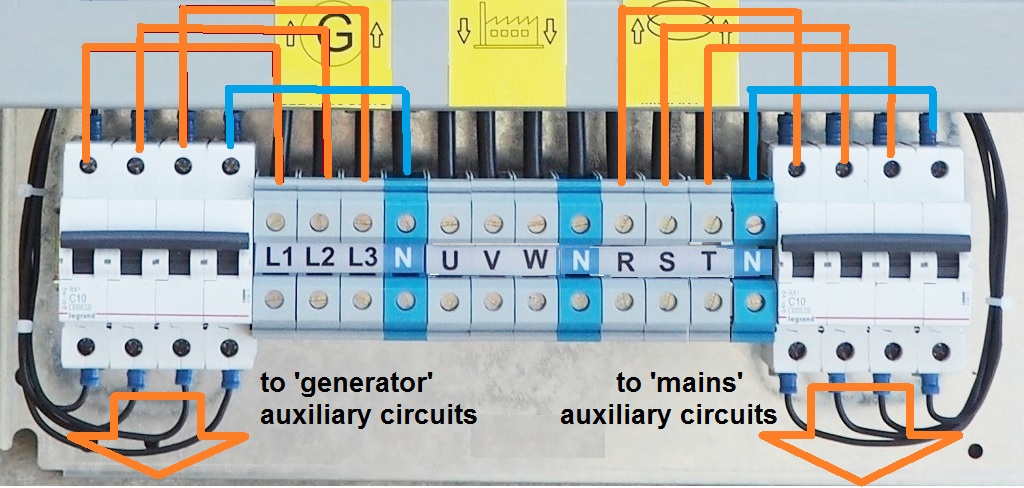

CIRCUIT BREAKERS INPUT CONNECTIONS

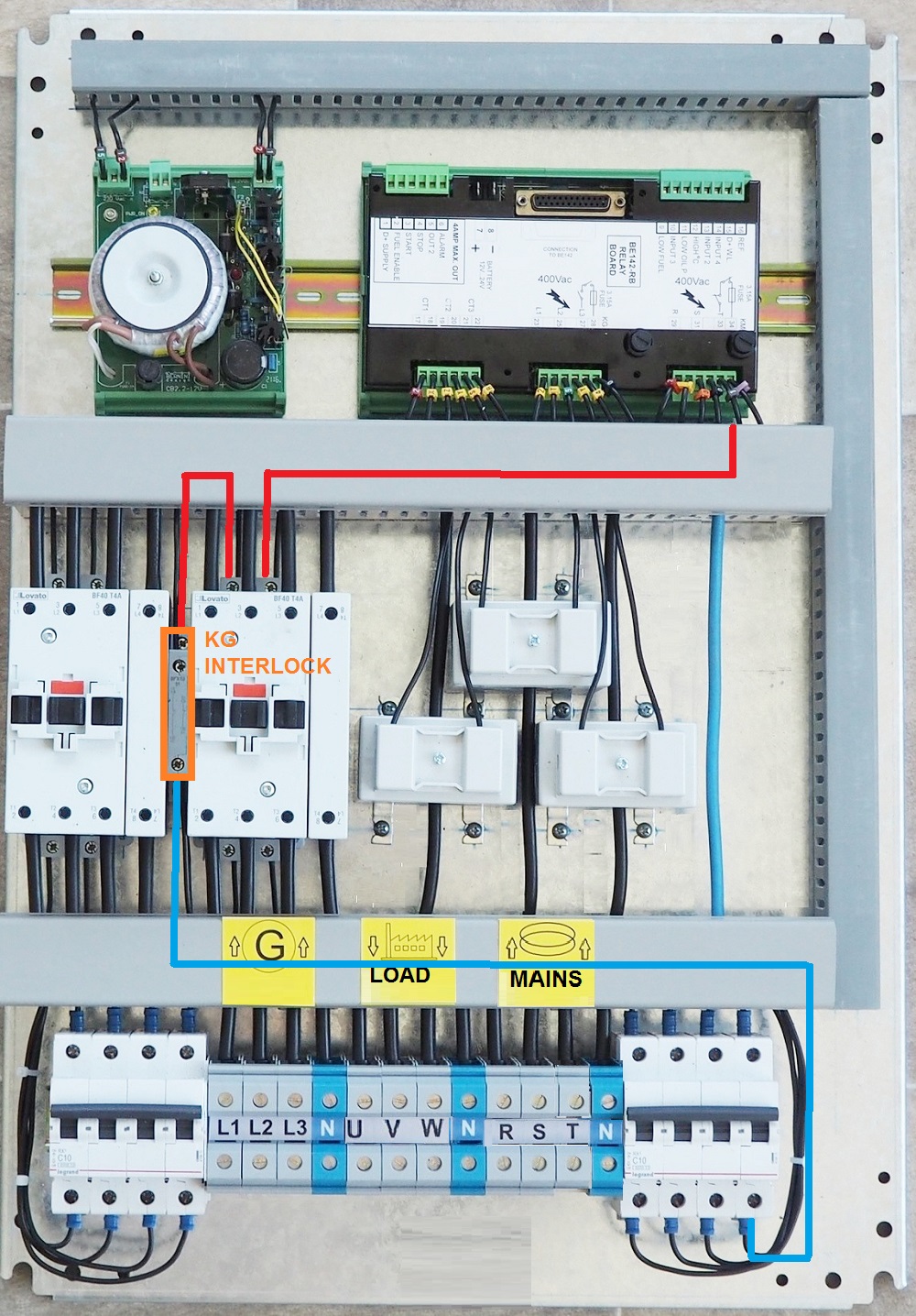

The controller has to sense the voltage of the utility power (mains) and a generator. You have to provide power to the contactors coils as well. It is quite dangerous to connect these loads to a high-power source. Utility power can be able to supply hundreds of amperes. For this reason, it is mandatory to put a circuit breaker that limits the current. This will prevent major damage in case of a short circuit. We consider that 10 Amps are more than enough for this application. Follow the indication of the picture. By turning OFF the circuit breakers, you can easily carry out maintenance to the parts without risk.

Connect Phases L1-L2-L3-N from the ‘generator’ terminal block to the entrance of the circuit breaker on the left side. Do the same connections for the circuit breaker on the right side by connecting the R-S-T-N terminal blocks. We recommend to use 1,5 square mm flexible stranded copper cable. See the above picture.

VOLTAGE MEASUREMENT CONNECTIONS

With this task, you will connect the voltage measurement circuits. You can see in RED colour the three cables for the generator voltage measurements (5-6-7). The three YELLOW cables provide voltage measurements of utility power (mains) (1-2-3). We recommend to use 1,5 square mm flexible stranded copper cable. See the picture below.

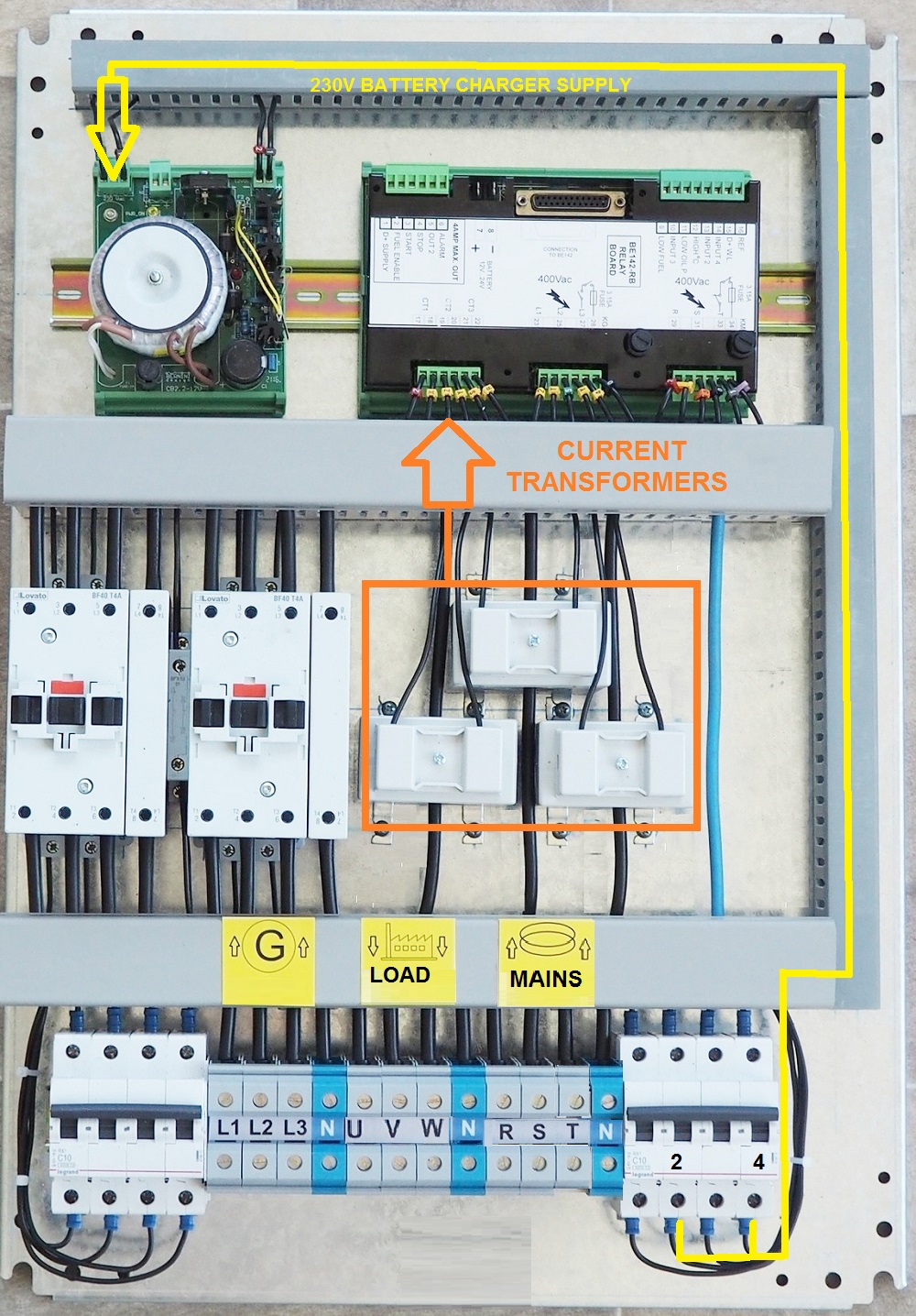

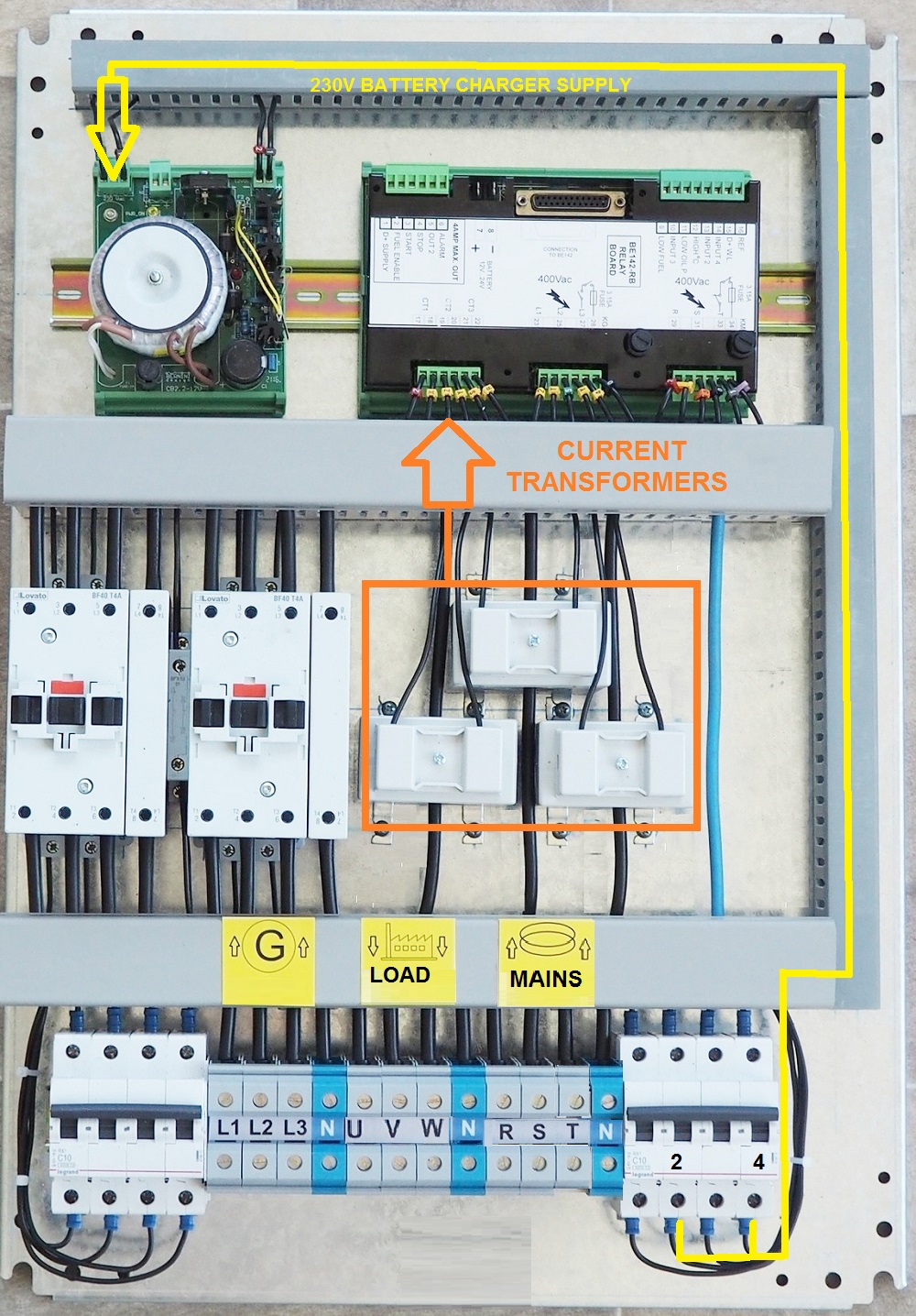

BATTERY CHARGER AND CURRENT TRANSFORMER

With this task, you will connect the current transformers to the BE242RB inputs. The end side of the common cable must be grounded. In this step, you are also required to connect the phase ‘2’ and neutral ‘4’ to supply the battery charger. We recommend using a 1,5 square mm flexible stranded copper cable. See the following picture.

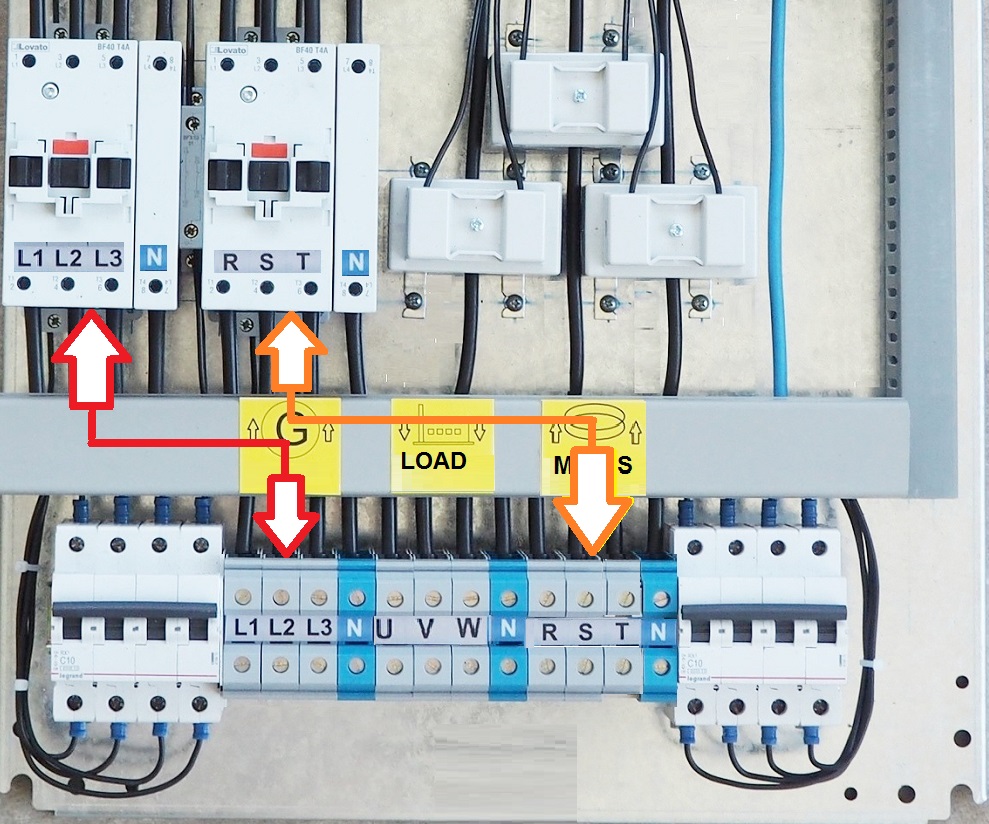

WIRING THE KG CONTACTOR AUXILIARY CIRCUITS OF AN ATS PANEL

You are required to wire the coil of the KG (terminals A1 & A2 on the left side) and the electrical interlock contacts of the KM (utility power contactor). Follow the wiring diagram and the below picture. According to the wiring diagram, the KG will only energize if the KM is OFF. The OFF position of the KM will hold closed the interlock auxiliary contact in a way that lets the KG coil energize. If the KM, for any reason, is in the ON position, the auxiliary contact, being in the open state, will not allow KG to energize. In blue color the connection to the neutral terminal of the generator via the circuit breaker.

WIRING THE KM CONTACTOR AUXILIARY CIRCUITS OF AN ATS PANEL

You are required to wire the coil of the KM (terminals A1 & A2 on the right side) and the electrical interlock contacts of the KG (GENERATOR power contactor on the left side). Follow the wiring diagram and the below picture. According to the wiring diagram, the KM will only energize if the KG is OFF. The OFF position of the KG will hold closed the interlock auxiliary contact in a way that lets the KM coil energize. If the KG, for any reason, is in the ON position, the auxiliary contact, being in open condition, will not allow KM to energize. In blue color the connection to MAINS neutral terminal via the circuit break

WIRING THE CONTACTORS INPUTS OF AN ATA PANEL

This is the most critical part of the job. Particular skills are required to connect the wires of big size. You have to follow the recommendations and instructions of the contactor manufacturer. This will avoid overheating of the connection points. You have to use the recommended force to guarantee good contact especially when high currents are involved (in this case the nominal current is about 110Amps). Connect phases ‘L1’-’L2’-’L3’-‘N’,connect phases ‘R’-‘S’-‘T’-‘N’

In choosing the size of the cables consider the table on page 7. According to the table, a 60kVA panel require a 25 sqmm size. This size will allow a continuous current of about 100 amps. For terminal blocks, the better choice is to use a 35 sqmm size.

WIRING THE CONTACTORS OUTPUT

This is the most critical part of the job. Particular skills are required in connecting the wires of big size. You have to follow the recommendations and instructions of the contactor manufacturer. This will avoid connections overheating. Currents over 100 Amps may circulate in these wires. Use the recommended force to guarantee good contacts. Connect phases ‘L1’-’L2’-’L3’-‘N’ together with the phases ‘R’-‘S’-‘T’-‘N’ Each output phase must enter the proper current transformer before connecting the terminal blocks. The neutral wire must be directly connected to the terminal block.

DRILLING THE DOOR OF THE PANEL

The main advantage of using the BE242 controller is time-saving. The BE242 is the only AMF ATS controller of square size that requires a round hole. This means that you can make the hole using a circular saw. You are required to download the template. Double-check the dimensions reported on the drawing. This is particularly important if you are not sure that your printer can print in 1:1 ratio. Choose the correct position for the template [1] over the panel [5]. Use a paper tape to fix and hold the template. Make a round hole between 56mm to 64mm. This will be the main hole for the BE242 controller. Make four holes [3] of about 4,5mm. These holes will allow you to fix the controller on the panel by using 4 nuts 4MA. You can additionally make a 22mm hole [4] if you need to install an emergency stop button. See the picture.

The quality of your panel & final checklist

Very well done. You are supposed to finish your panel. Your work is not over yet. We recommend that you print the following checklist. Check carefully, step by step, each item. This is a general guide. You can integrate it based on your experience.

1) The controller is very well fixed on the front door. Make sure the nuts are tight. The surface of the panel is clean.

2) Make sure the nuts for the grounding of the front door and panel structure are tight.

3) The backplane that supports the hardware is normally held in place by 4 bolts M6. Make sure you have a spacer between it and the frame of the panel. Being the bolts soldered, if you apply too much force, without a washer spacer, you can de-solder the bolts.

4) Verify that all screws of the terminal blocks, fuse holders, CTs, circuit breakers, and auxiliary contacts are properly tight.

5) Verify that there are no strands exposed on each cable termination. You could get arcing or overheating.

6) Check if the bolts, or screws, on the contactors, are tight according to the contactor specifications.

7) When using multipolar connectors check the holding screws: must be tight.

8) The emergency switch on the front door must be carefully verified. If necessary use thread locker adhesive to avoid rotation of the switch.

9) Verify the size of the fuses. Put a proper label indicating the value. Add spare fuses for the user.

10) Check the free mechanical movement of the contactors. Check the mechanical interlock. You must not be able to activate both contactors. The mechanical interlock will allow only one contactor at a time.

11) Hold the panel in a vertical position. Hit gently the panel with a rubber mallet. Check for vibration and collect various dirty remains (iron filings, copper remains and so on) on the bottom of the panel. Use a powerful vacuum cleaner. Make sure there are no extra items (screws, loose terminals, tools, pieces of wire and so on)

12) Verify the presence of the labels indicating Mains, Generator, Load, Phases, Electric Danger and so on.

13) Put inside the door an adhesive sheet that illustrates the schematics and the nominal data of the panel. This may help an electrician in case of service.

14) Mechanically check the closure of the door. If your panel is over IP42, check the gasket.

15) Proceed with electric test. The contactors, when activated, should not emit noise. The presence of noise could be caused by iron filing pollution on the body of the contactors.

16) Make sure the settings of the ATS controller match the size of the current transformers.

17) Remove all connections after testing. Tight the bolt again without forgetting the washers (this is in case connections are directly made on the contactors)

18) Do not forget to put on a small box, or envelope, the spare Panel Fasteners. It will be important for the user.

19) Close the door of the panel. You can proceed with the final packaging.

PURCHASE AN ATS PANEL READY FOR THE INSTALLATION

Tired to work? Do not worry we can make the best ATS panel for you- We offer basic versions and custom-made ATS panels

BERNINI DESIGN SRL

ITALY Industrial Park

46035 OSTIGLIA

SUPPORT

+39 335 70 77 148