Low Battery Generator Auto Start Module

This is a cost-effective solution to prevent low battery condition on your generator. It interfaces with your auto start controller. As an option, you can connect two relays and make your own Auto Start Relay.

When the battery rises above the HIGH BATTERY VOLTAGE threshold (2), the delay timer (4) will start to count. When the timer (4) will expire, the engine will automatically stop.

PURCHASE THE LOW BATTERY AUTO START MODULE

The Be-1 Auto Start Controller Connections

GROUNDED IN THE CORE OF ELECTRICAL RULES

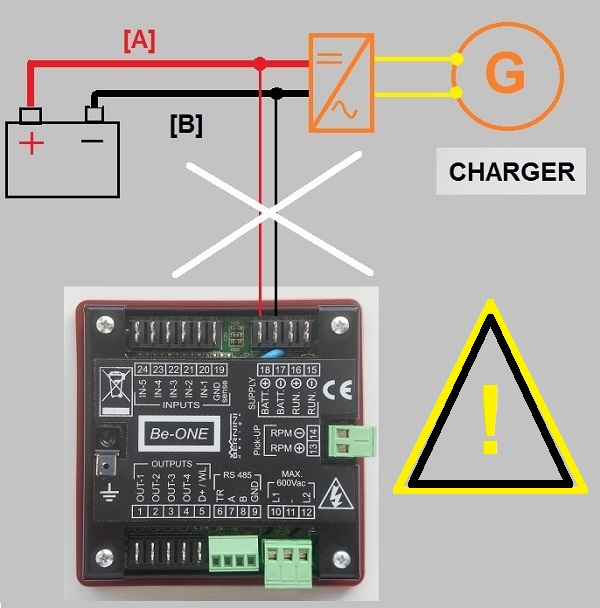

Do not connect the device as indicated in the following picture. When the charger delivers current, the drop of voltage on wires [A] and [B] generates high errors. You can experience with 1V of error. Connecting the correct point for the measurement is vital for a LOW BATTERY AUTO START module.

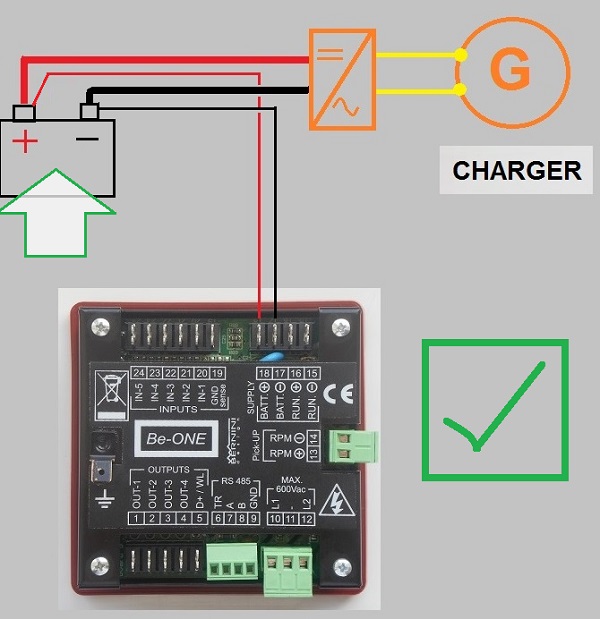

This is the correct way to connect the Low Battery Auto Start Module. The measurement cables are directly connected to the battery. This connection will allow precise battery voltage measurements.

This is the correct way to connect the Low Battery Auto Start Module. The measurement cables are directly connected to the battery. This connection will allow precise battery voltage measurements.

For the connection use of 1.5sq. mm improves reading precision.

USER-FRIENDLY SETUP INSTRUCTIONS

To make the Low Battery start working, use a REMOTE START input. The Be1 only monitors this input in AUTO mode of operation. OUTPUT nr. 4 (terminal #4) and INPUT nr. 4 (terminal #23) are utilized in this example.

HARDWARE SETUP

- Program the parameters P0 and P1 (see table 7.00) to add a delay in starting and stopping the engine. Default settings are 5 secs. Longer timing will avoid unstable operations.

- Verify that OUTPUT4 is not being used for any other purpose and that INPUT4 has the option [12] (by default).

- Make sure that the polarity of the INPUT4 contact is [n.o.] (that is the default).

- Enter the programming mode to set the output 4 with the option [15] (the default is [4]).

- Connect the output “4” (terminal#4) to the input “4 “ (terminal#23).

SOFTWARE SETUP

- Remove the DC supply. Push and hold the button [0], and at the same time turn the supply on. Hold the button [0] until the message [Lobt] is displayed. Release the button [0].

- To adjust the low battery threshold [Lobt], push and hold [?]. Push [AUTO] to increase or [ I ] to decrease the setting. Release the button [?].

- To select the [Hibt] threshold, push the button [→]. To adjust the [Hibt] setting, push and hold [?]. Push [AUTO] to increase or [ I ] to decrease the setting. Release the button [?].

- Save the settings by pushing and holding together the buttons [ACK] and [→] for about 5 seconds.

The Be1 starts the engine when the battery voltage falls below the [Lobt] threshold after expiring the [P0] delay. The Be1 stops the engine when the battery voltage rises above the [Hibt] threshold after expiring the [P1] delay.